The future of packaging starts with washing

7 — 13 May, Düsseldorf, Germany INTERPACK 2026

Date and time

7 — 13 May 10:00h - 18:00h

Location

Düsseldorf, Germany Hall A5, Stand A04

Mimasa is proud to participate in Interpack 2026, the world’s leading trade fair for packaging and processing technologies, bringing together the entire value chain across food, bakery, confectionery and related industries.

In 2026, Mimasa celebrates its 40th anniversary, marking four decades of experience in the design and manufacture of industrial washing, sanitizing and drying solutions for the food and packaging industries, always ensuring the highest standards of hygiene and food safety.

Ultimate insights in design for food industry

Mimasa at INTERPACK - Explore our equipment

Strongly committed to sustainability, Mimasa develops custom-made equipment tailored to each customer’s requirements, optimizing water consumption, energy efficiency and production capacity to support more responsible and efficient industrial processes.

Visit our booth to discover our latest innovations and explore how Mimasa can help you improve hygiene, efficiency and sustainability throughout your production and packaging operations.

See you at Interpack 2026.

-

Tray Washing tunnel

LBK-800

The LBK-800 ensures top hygiene with a fully open, easy-to-clean design—no flat surfaces, continuous welds, and tool-free removable parts. It’s custom-built to fit each layout and cleaning need, with optimized washing circuits and full integration into production lines.

Its double-wall chassis, sealed doors, and self-cleaning filters guarantee watertightness and performance. Energy-efficient and quiet, it features IE3 motors, controlled water use, and a powerful drying system—making it ideal for demanding industrial environments.

Learn more -

Industrial sanitizing tunnels

MD-100

The sanitizing tunnel MD-1000 is the ideal solution for a perfect disinfection of the big sized meat logs, cheese logs and other products, before getting into the cleanroom. Thanks to the atomizing technology we can disinfect all the geometry of the element, creating a thin protecting film. With a consume up to 8 times lower than traditional disinfection processes, the efficiency of these systems is unrivalled.

Learn more

Applications: disinfection of meat logs, products, trays, and any element before entering a cleanroom. -

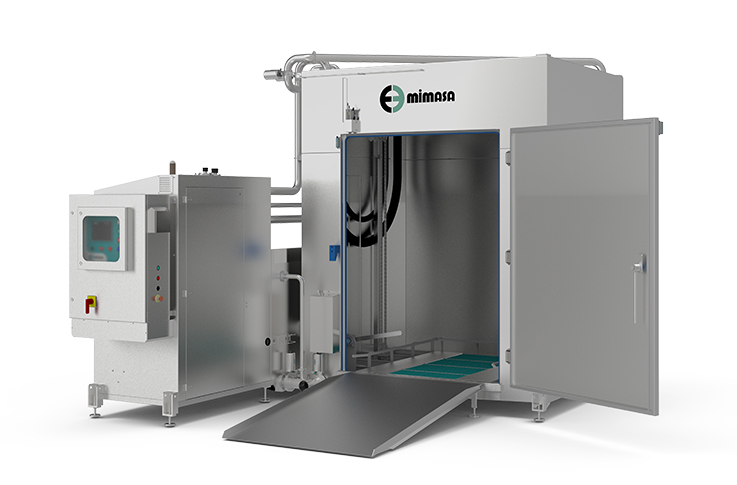

Rack Washer

REA-2500

The Rack Washers washes frames, shelves, and cages. With several panel and sprayer configurations we make sure that your rack is perfectly cleaned. This model is designed to solve all those cases where it is not possible to make a pit to install the cabinet in. Optional double interlocked doors separate the high- and low-risk areas. An optional double jacketed cabinet and tank prevent the dispersion of heat produced by the washing process. These offer a reduction both in energy consumption and noise levels. Different automatic filters with self-cleaning features ensure correct continuous working conditions, as well as reducing the consumption of chemicals and heat energy.

-

Customized washing solutions

We are obsessed to develop our solutions, to adapt them to the customer needs, and we are passionate for showing them proudly and say: this was thought, designed and manufactured by us, and cleans marvelously. And specially these tailor-made projects are one of the motors of this continuous improvement, as hand by hand with our customers, we go further. Your needs, your problems, are challenges for our designers, and help us to generate new solutions and to apply them on the standard units.

Request Free Admission to INTERPACK

We have a limited number of complimentary tickets for admission to INTERPACK. If you’d like to be entered to win free entry to the show as our guest, fill out the form, and we’ll be in touch if you’re selected.