- Products

- Ham washers

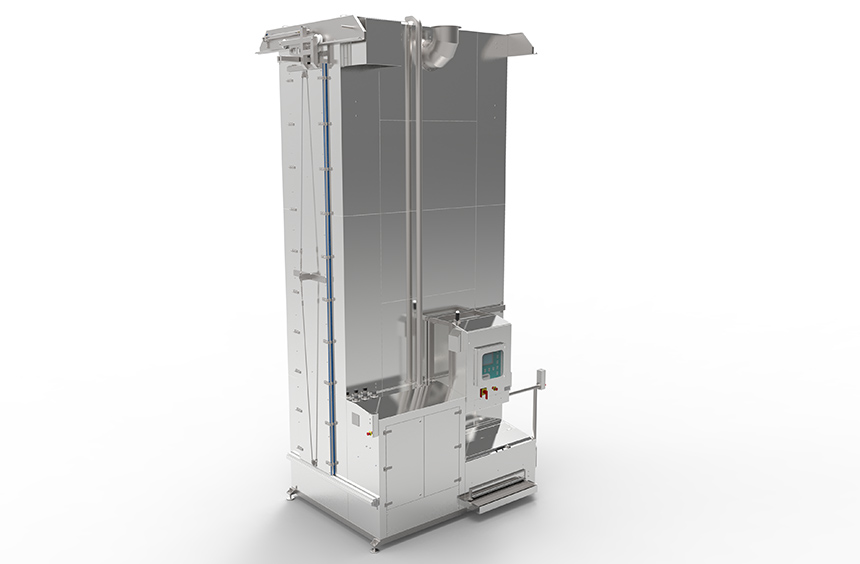

- Rack washer RE-2500-R (rotary)

Washing with the rack in rotation

The rack washers, also prepared to wash frames, shelves, cages, are part of the RE series. This series has been completely redesigned in 2020 with the aim of achieving a superior level of efficiency and hygiene. With several panel and sprayers configurations, we make sure that your rack will be perfectly cleaned in all its corners, no matter what kind and level of soil to be removed. Also used for product washing: hams, salami, dry sausages… The model RE-2500-R incorporates a rotary platform that continuously turns the rack during the washing process, exposing it to a high-impact rotary manifold. This way it is capable to eliminate the most incrusted and hidden soil. Thanks to its configuration, this model can also include a drying stage.

Mimasa Technology

-

Hygienic Design

Retention zones and 90º angles elimination, continuous welding, great accessibility. Let water flow!

-

Virus & Bacteria Neutralize

Remove the surface contamination of virus and bacteria, improving the food safety.

-

UltraFast

CleanWe combine technology, temperature, chemistry and mechanics to obtain a total disinfection in record time.

-

Plug & Clean

We design our systems to be easy to assemble, install and connect.

-

The 10-Sides

TechnologyTen sides that need to be cleaned. Mimasa does not forget any of them.

Technical Features

-

Maximum clearance (LxWxH)

1.300x1.300x2.000mm (ask for bigger dimensions)

-

Production

20 to 25 units/h

-

Pump power

18,5KW

-

Filtering

Self-cleaning rotary filter

-

Washing system

Element on a rotary platform. Fixed manifold with rotary jets

-

Stages

Prewash-Wash-Rinse-Disinfection

-

Heating

Steam or electrical (other options available)

-

Pit

Yes (contact us for non-pit versions)

- Options and accessories

- Automatic or manual doors

- Two-doors systems to separate clean and dirty areas

- Steam exhaust systems

- Detergent and disinfectant dosing devices

- Conductivity control

- Automatization for loading and unloading

- Special racks to clean all kind of elements such as palets, buckets, trays, utensils…

- Drying stage

Associated Machines

-

![]()

Hygienic Design

We apply hygienic design technology to all Mimasaa washing, sanitizing and drying systems. The three key concepts are: elimination of right angles, maximizing water flow, and giving maximum accessibility for cleaning.

+