- Products

- Container washers

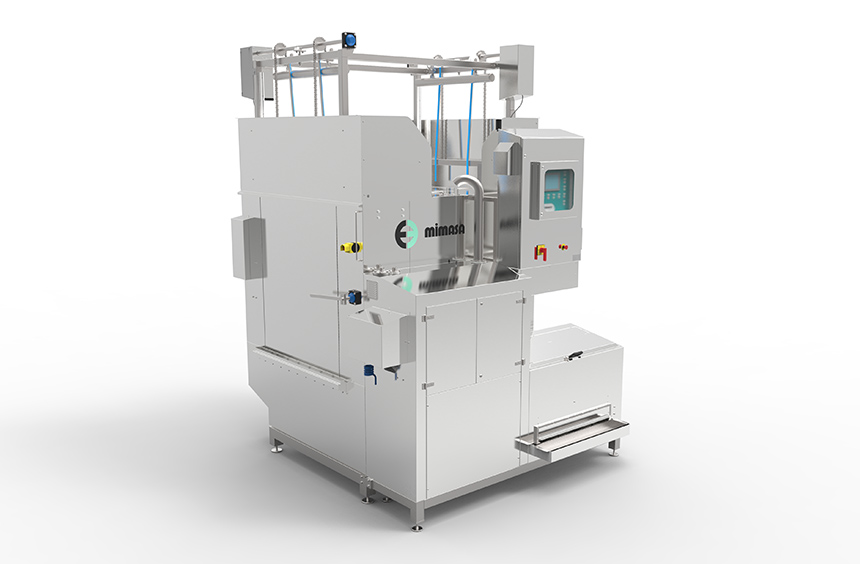

- Vat and bin washer LC-1500 cabinet

All sides are important

The LC series cabinet washers are the ideal solution to clean those elements that require to be dumped upside down to get a proper washing and disinfecting result. Specifically, the model LC-1500 has been designed for the sanitizing of the vats or palbox, ensuring a perfect wash of the internal zone, with special attention to the internal walls, but not forgeting the wheels area. Maximum efficacy and minimum energy consumption, thanks to its design, that allows water and energy consumption optimization. Washing and disinfection of vats, bins, palbox, bigbox, containers.

Mimasa Technology

-

Hygienic Design

Retention zones and 90º angles elimination, continuous welding, great accessibility. Let water flow!

-

Virus & Bacteria Neutralize

Remove the surface contamination of virus and bacteria, improving the food safety.

-

Plug & Clean

We design our systems to be easy to assemble, install and connect.

-

The 10-Sides

TechnologyTen sides that need to be cleaned. Mimasa does not forget any of them.

Technical Features

-

Production

20 to 25 units/h

-

Maximum size of the element to be cleaned

1200x1200x1100mm (Wide x Long x High)

-

Loading and unloading

On the same side

-

Cleaning position

Turned upside down 180º

-

Pump power

22.5KW

-

Filter

Self-cleaning rotary filter

-

Stages

Prewash-Wash-Rinse-Disinfection

-

Heating

Steam or electrical. Other options available

- Options and accessories

- Steam exhausting systems

- Detergent and disinfectant dosing systemse

- Conductivity control

Associated Machines

-

![]()

Your tailor-made project

We design and manufacture tailor-made washing and sanitizing systems that are designed for each specific sector and companmy to fit their production needs.

+ -

![]()

At your side

Mimasa is by your side during the entire process. We help you choose the right solution for your application, we provide start-up and training, and we provide after sale parts and service. We are here when you need us most.

+