- Products

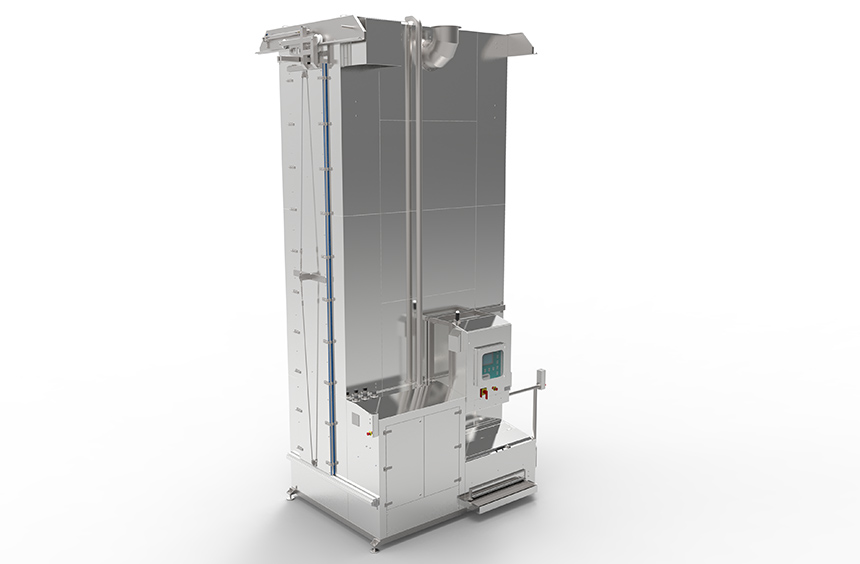

- Tree rack washers

Cabinets and tunnels

for tree washing

Mimasa offers all kind of solutions for washing and disinfecting, racks, trees, trolleys, frames, cages, etc. Batch systems (cabinets) and continuous systems are available. Each model can be customized to adapt it to the production needs and to the available space of each customer.

According to the element to clean and the kind of soil, we adapt the manifolds and automatisms. We manufacture cabinets to wash one or various units per cycle. The experience of Mimasa guarantees equipment with minimum water, energy and chemicals consumption. Cabinets can be installed in a pit or at floor level.

We design considering the highest hygiene standards and thinking in the “washability” of the washer. From the smallest cabinet to the biggest tunnel, all of them can be manufactured with more than one recirculation tank, according to the application, and always with high quality standards and first international brands components.

The washing program can be adapted to the kind and level of soil. Optionally we have dosing devices for detergent and disinfectant, steam exhaust, HACCP control programs, solids separation filter, automations for loading and unloading, different heating systems, automatic doors, etc.

We also manufacture special racks to use the washer to clean also other elements such as utensils, bins, vats, etc.

Customized project of tree rack washers

![]()

At your side

Mimasa is by your side during the entire process. We help you choose the right solution for your application, we provide start-up and training, and we provide after sale parts and service. We are here when you need us most.

+![]()

Your tailor-made project

We design and manufacture tailor-made washing and sanitizing systems that are designed for each specific sector and companmy to fit their production needs.

+