- Sectors

- Pool and Logistics

Washing systems

for the pool sector

Pools companies manage a wide range of containers references: foldable crates, nestable crates, rigid crates, trays, half-crates, boxes, bins, plastic containers, pallets, half-pallets…)

Quite often all these references are mixed, so the washing tunnel must be able to wash them without being classified. Mimasa’s tunnels use a resourceful guided system that allows washing containers with different heights and more over, with completely reliability.

Labels were a warhorse for pools companies and nowadays they still are. Frequently containers are plenty of different labels, made of several materials, with various glues and moreover they are in different positions in the pallbox or in the crate. Mimasa has developed a reliable solution, without water consumption, without changing pieces that are often worn and with guaranteed results. This has been possible thanks to lots of years of work, tests and the collaboration with ours costumers, to develop a system that join the impact, the projection and the filtration that achieve removing all the labels. The solution was tested in real conditions and it is already working in several units that have been made recently.

As all these problems are typical from pool companies; labels are so a problem for the most of companies in the different sectors, so the speed production is every day higher for the box, pallets and containers washing machines, that is why several food production plants have decided to install logistic centers to receive and clean containers, as if it were about a pool’s platform.

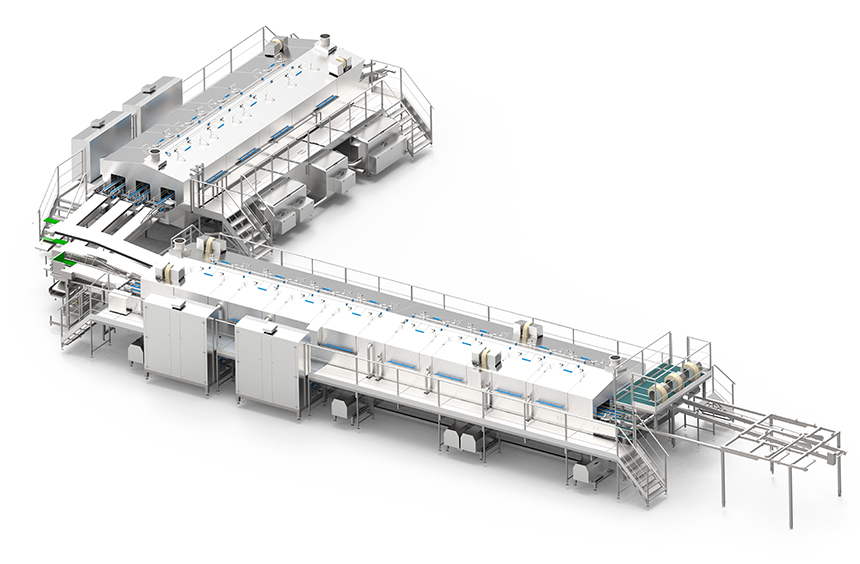

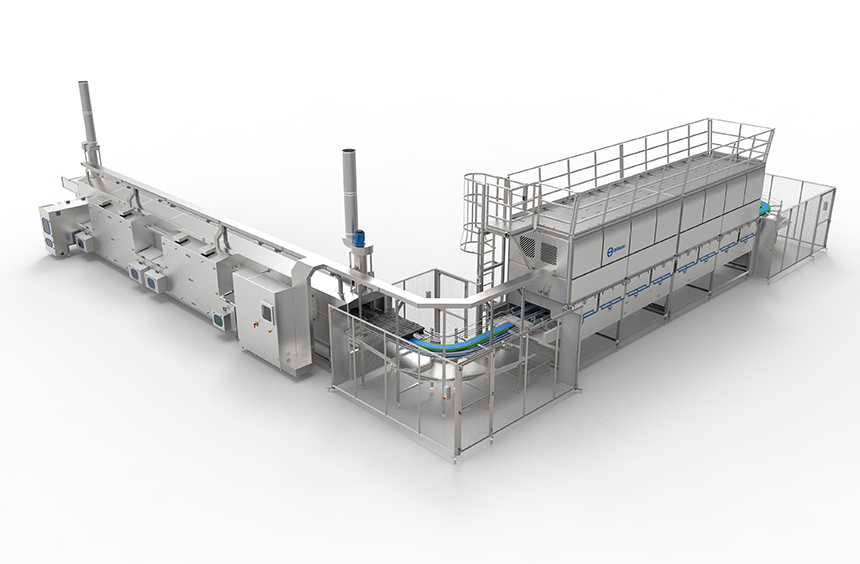

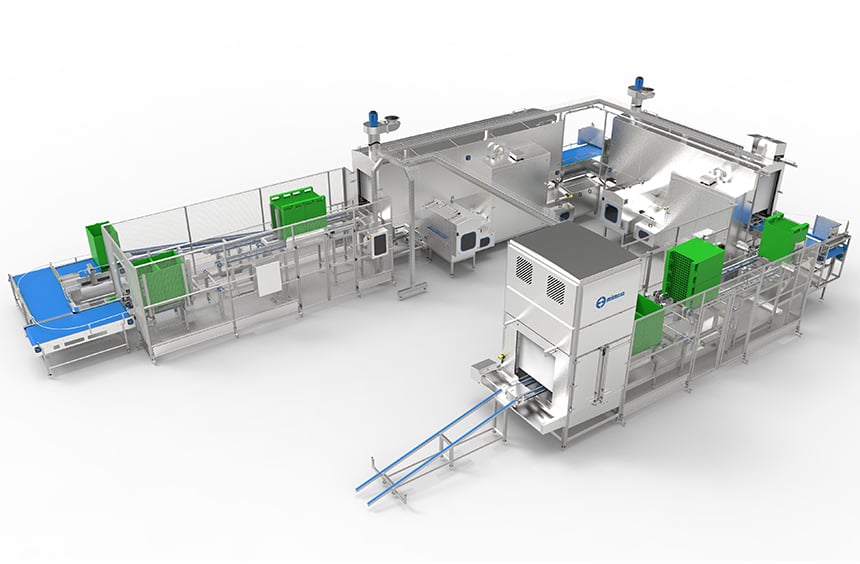

Washers for the sector pool and logistics

Customized washers for the sector pool and logistics

![]()

Your tailor-made project

We design and manufacture tailor-made washing and sanitizing systems that are designed for each specific sector and companmy to fit their production needs.

+![]()

At your side

Mimasa is by your side during the entire process. We help you choose the right solution for your application, we provide start-up and training, and we provide after sale parts and service. We are here when you need us most.

+