- Products

- Container washers

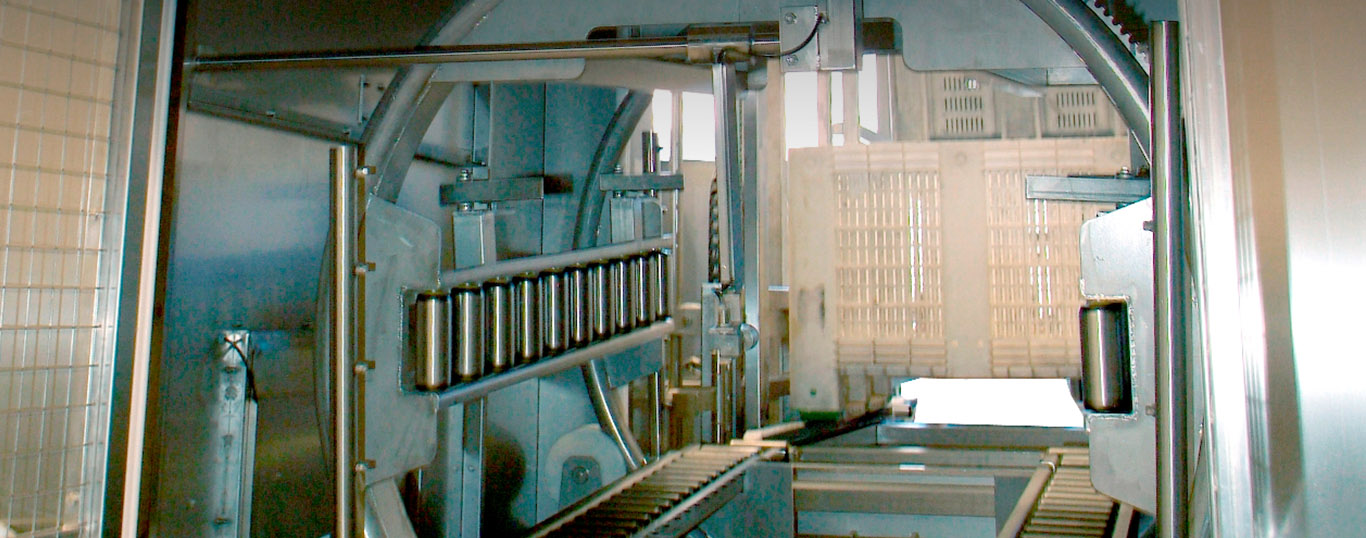

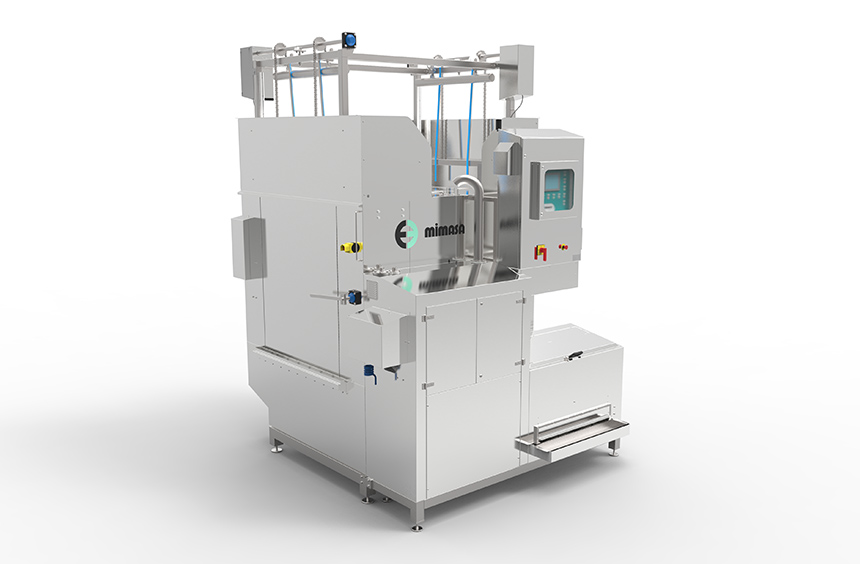

- Vat and bin rotating washer LCR-1000

Intelligent solutions to clean vats separating inlet and outlet

The LC series cabinet washers are the ideal solution to clean those elements that require to be dumped upside down to get a proper washing and disinfecting result. Specifically, the model LCR-1000 has been designed for the sanitizing of the vats or palbox, ensuring a perfect wash of the internal zone, with special attention to the internal walls, but not forgeting the externals ones. Maximum efficacy and minimum energy consumption, thanks to its design, that allows water and energy consumption optimization. Washing and disinfection of vats, bins, palbox, bigbox, containers.

Mimasa Technology

-

Hygienic Design

Retention zones and 90º angles elimination, continuous welding, great accessibility. Let water flow!

-

Virus & Bacteria Neutralize

Remove the surface contamination of virus and bacteria, improving the food safety.

-

Born to be Automated

To facilitate the automatization of the sanitizing processes. Washing systems born to be automated.

-

The 10-Sides

TechnologyTen sides that need to be cleaned. Mimasa does not forget any of them.

Technical Features

-

Production

20 to 25 units/h

-

Loading and unloading

Inlet and outlet separated

-

Cleaning position

Continuous rotation 360º

-

Pump power

22.5KW

-

Filter

-

Stages

Prewash-Wash-Rinse-Disinfection

-

Heating

Steam or electrical. Other options available

- Options and accessories

- Steam exhausting systems

- Detergent and disinfectant dosing systemse

- Conductivity contro

Associated Machines

-

![]()

Your tailor-made project

We design and manufacture tailor-made washing and sanitizing systems that are designed for each specific sector and companmy to fit their production needs.

+