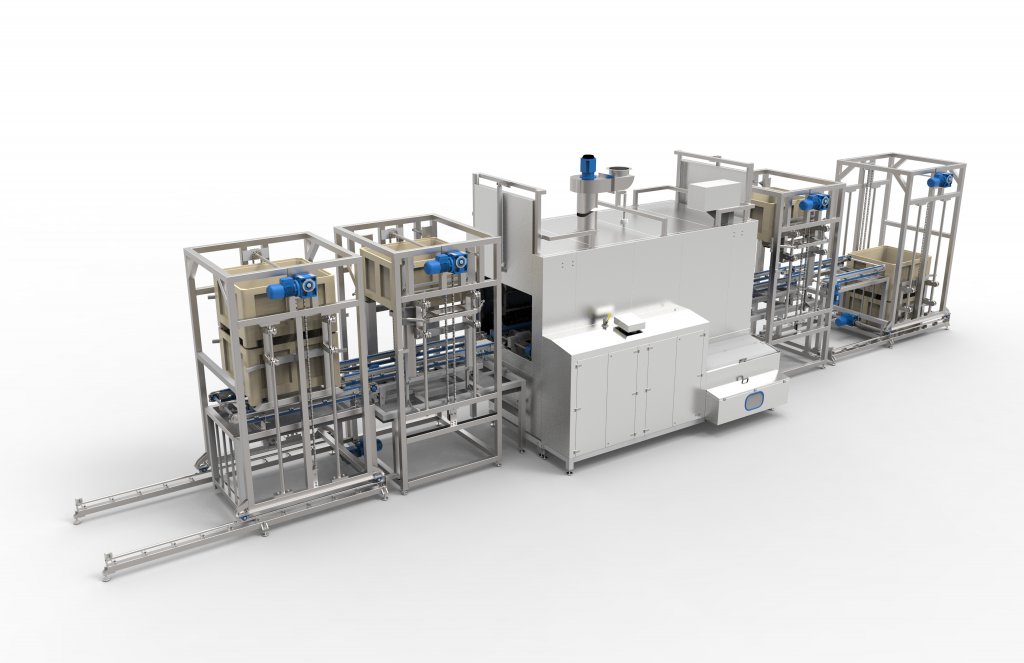

- Tailor made projects

We design your tailor-made washing system

The washing machinery sector has suffered an evident evolution along the last years. What for long time was considered auxiliar equipment, even many times installed in the exterior of the production plants, has slowly moved into the production process. Nowadays is very common to find our washing and drying systems situated not only in the production plant but being part of the processing line. This fact has increased the level of exigency and the customization needs of our customers.

From the beginnings, Mimasa has been always known by our capacity with tailor-made solutions. Our sales team, our projects department, our technicians…all our company has in the DNA this spirit for creating the solution that fits like a glove on our customer needs. There where no one has ventured to go, you will find us, looking for the most effective way to automate, integrate and implement a washing and drying system.

-

Adapted to your sector

-

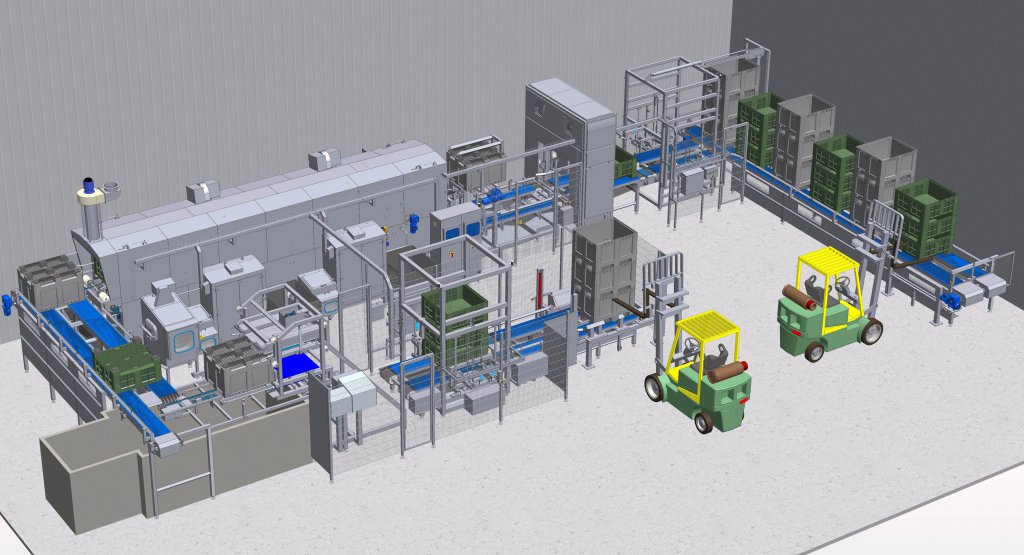

Integrated in the production line

-

Complying with all technical requirements

-

Customized production capacity

In Mimasa we are restless people, non-conformist and we always look a little bit further. Improving our equipment, cleaning the most hidden corners, creating more hygienic and accessible systems. We are obsessed to develop our solutions, to adapt them to the customer needs, and we are passionate for showing them proudly and say: this was thought, designed and manufactured by us, and cleans marvelously. And specially these tailor-made projects are one of the motors of this continuous improvement, as hand by hand with our customers, we go further. Your needs, your problems, are challenges for our designers, and help us to generate new solutions and to apply them on the standard units.

Mimasa Technology

-

Virus & Bacteria Neutralize

The washing and sanitizing systems of Mimasa remove the surface contamination of virus and bacteria, improving the food safety.

-

Ultra Fast Clean

We combine technology, temperature, chemistry and mechanics to obtain a total disinfection in record time.

-

10-Sides Technology

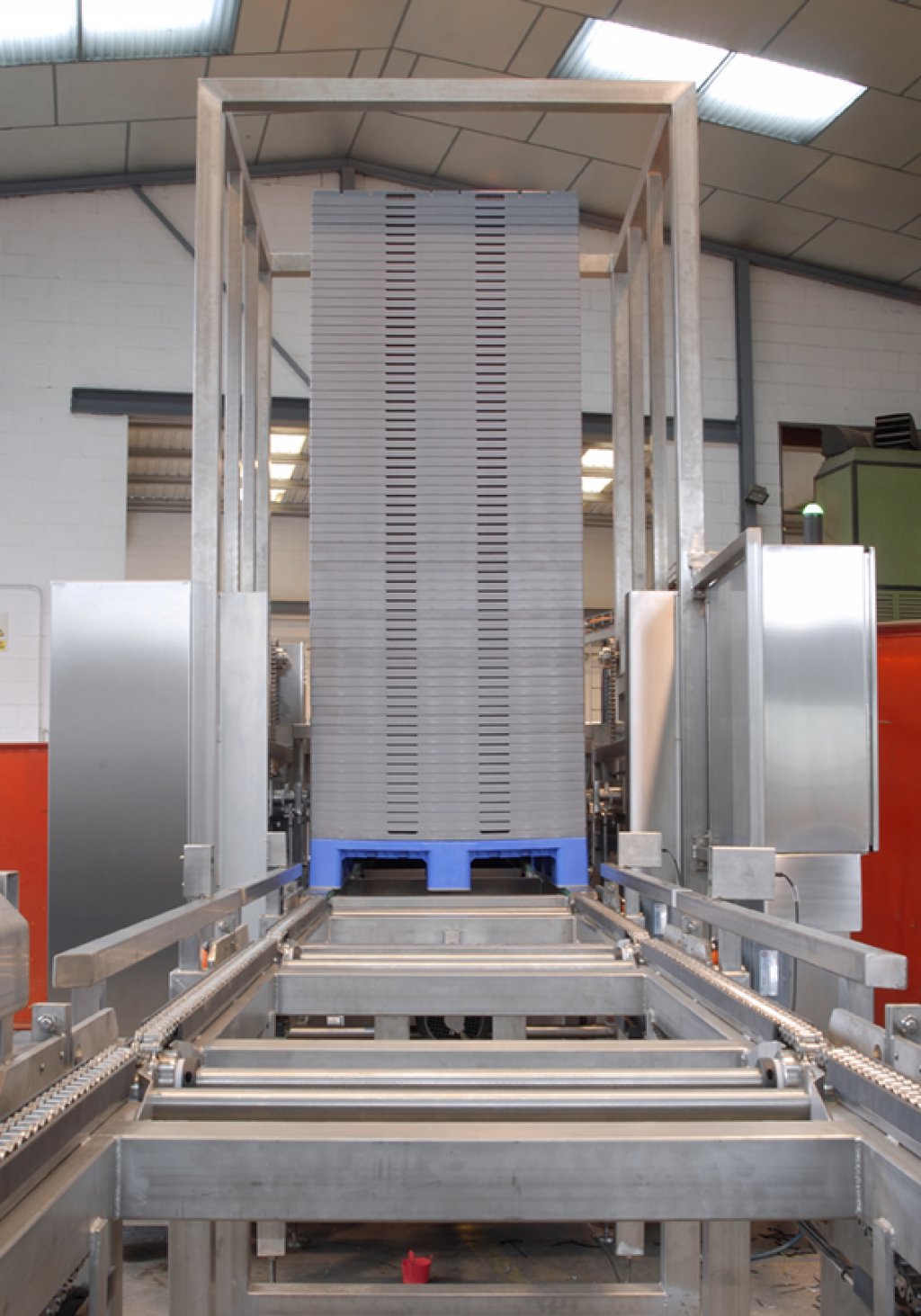

Elements such a buggy, a vat, a bin, or others have 10 sides that need to be cleaned. Mimasa does not forget any of them. We design our systems keeping in mind each one of the sides.

-

Plug & Clean

We design our systems thinking on them to be easy to assemble, to install and to connect. We use technology to manage, monitor and support remotely a start-up and we provide didactic material to make this process a child’s play

-

Labels Removal

Special modules for the label removal from crates, trays, RPC, palbox or palets. Ready to be integrated in washing systems, for plastic and paper stickers, at any speed.

-

Clean ad Aeternum

Never stop cleaning! The best filtering combination of the market, systems that allow safe interventions without stopping the line and solutions for the auto diagnostic.

-

Hygienic Design

Retention zones and 90º angles elimination, continuous welding, great accessibility. Let water flow!

-

Spin Dry

The spin-drying system that improves the drying results and reduces the consumption, the space and the operational costs. Multiple options for different production speeds.

-

Heat Recovery

Thermal isolation and energy recovery systems in our machines to reduce the thermal losses and to foster the energy savings.

-

Born to be Automated

To facilitate automatic loading and unloading, the buffers, the zones separation and the automatization of the sanitizing processes. Washing systems born to be automated.

![]()

Hygienic Design

We apply hygienic design technology to all Mimasaa washing, sanitizing and drying systems. The three key concepts are: elimination of right angles, maximizing water flow, and giving maximum accessibility for cleaning.

+![]()

At your side

Mimasa is by your side during the entire process. We help you choose the right solution for your application, we provide start-up and training, and we provide after sale parts and service. We are here when you need us most.

+