- Products

- Frame washers

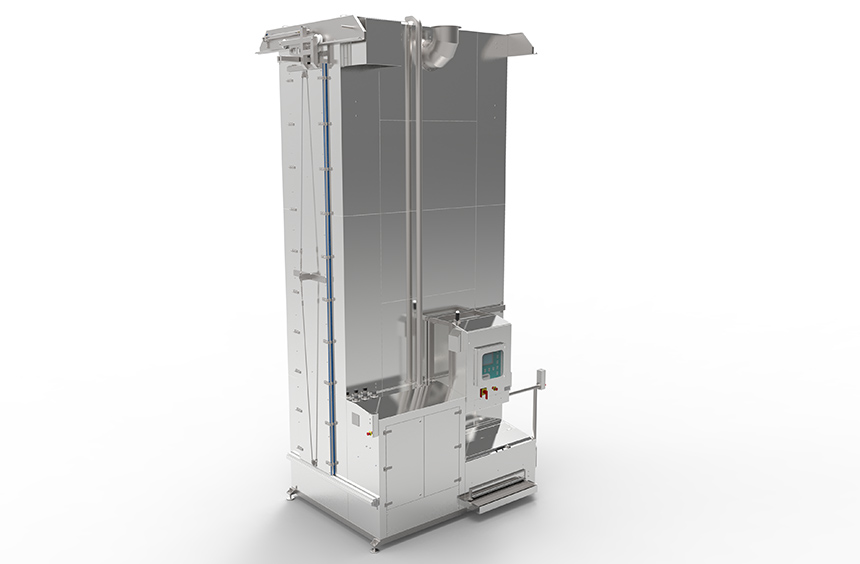

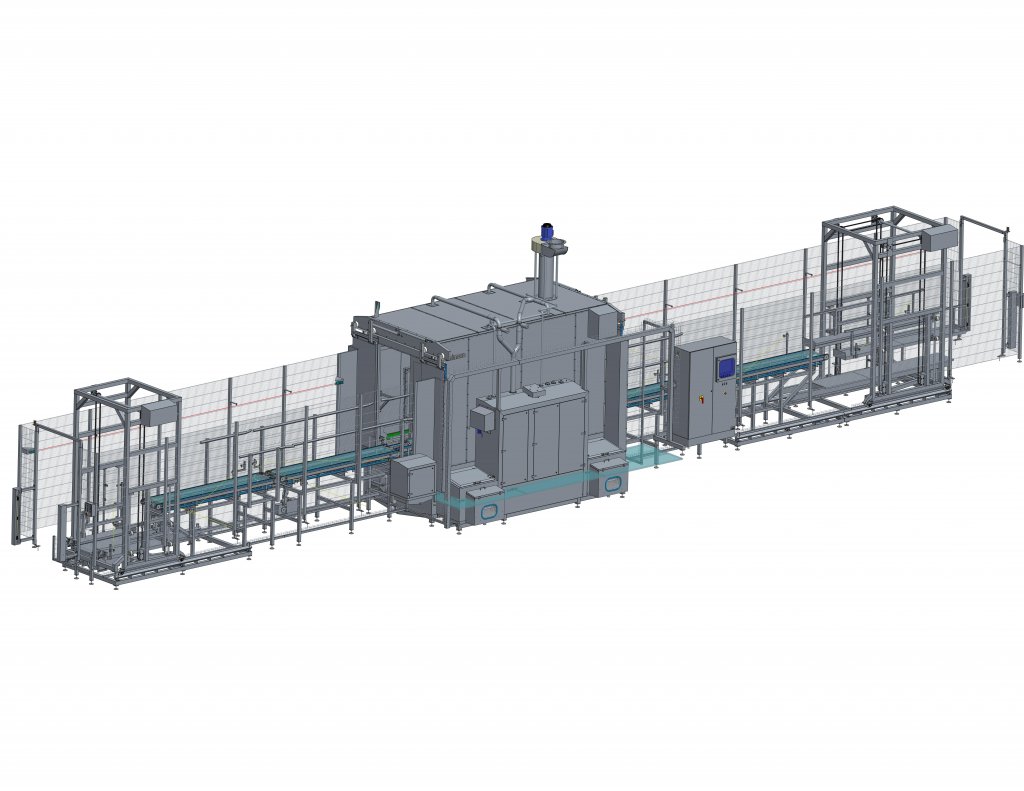

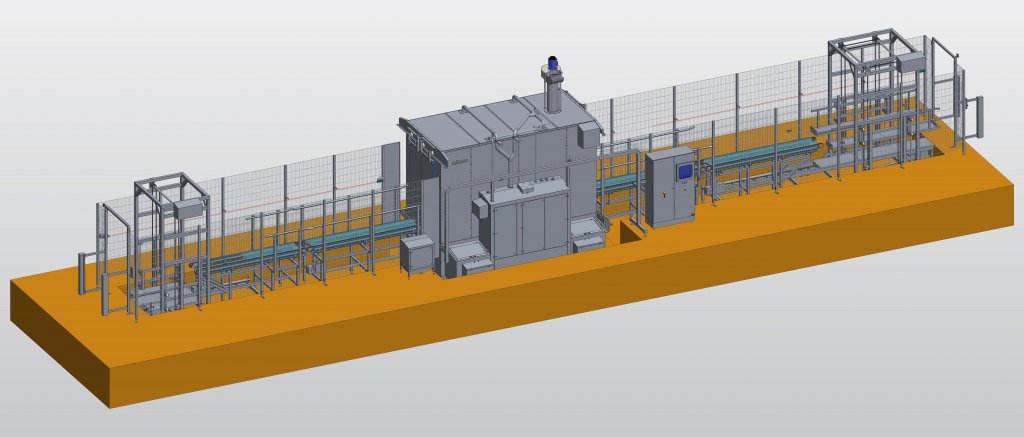

Frame washer machine

Mimasa accumulates years of experience in solution for the washing and disinfection of frames. Depending on the production needs of each customer, Mimasa designs and manufactures tailor-made systems rather batch (cabinets) or continuous (tunnels). In the case of the cabinets, they can be adapted for the cleaning of one unit per cycle, reaching the 15-20 units per hour, or two by two, reaching (30-35 units per hour). In the case of the tunnels we can reach much higher productions, arriving to 200 and even more frames per hour. These systems are designed based on the highest hygienic standards, thinking in making the cleaning and maintenance process very easy and fast. All the equipment is manufactured with first quality materials, using worldwide first brands, and offering a exceptional optimization in the water, energy and chemicals consumption.

The cabinet washers can have more than one tank depending on the application, as the tunnels can be composed of different modules of prewash, wash, recirculated rinse, etc. In the case of the cabinets, the washing programs can be adapted according to the level of soil. Optionally there is the possibility to install HACCP control programs, chemical dosing devices, steam exhaust, helicoidal filters to separate solids, CIP functions, loading and unloading automations, different heating systems, etc.

Models of frame washers

Customized project of frame washers

![]()

At your side

Mimasa is by your side during the entire process. We help you choose the right solution for your application, we provide start-up and training, and we provide after sale parts and service. We are here when you need us most.

+![]()

Your tailor-made project

We design and manufacture tailor-made washing and sanitizing systems that are designed for each specific sector and companmy to fit their production needs.

+