- Sectors

- Confectionery

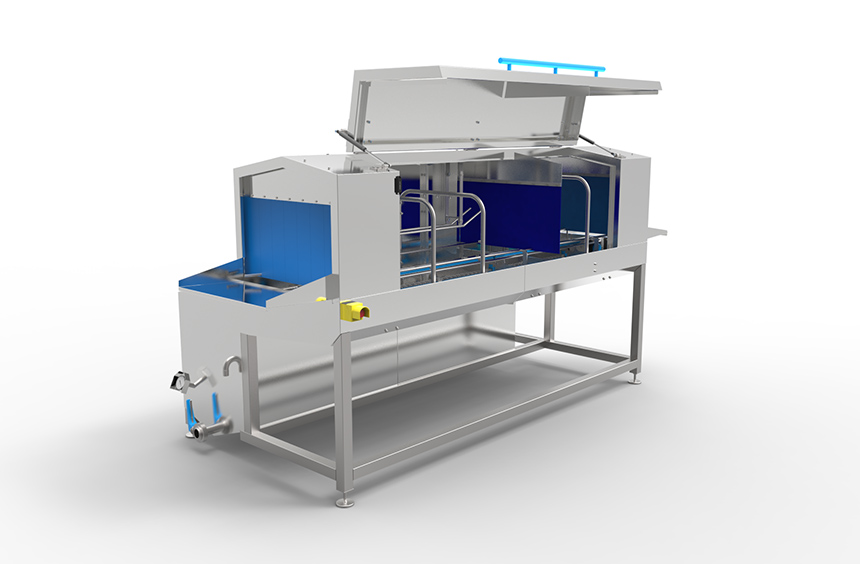

Washing systems

for confectionery sector

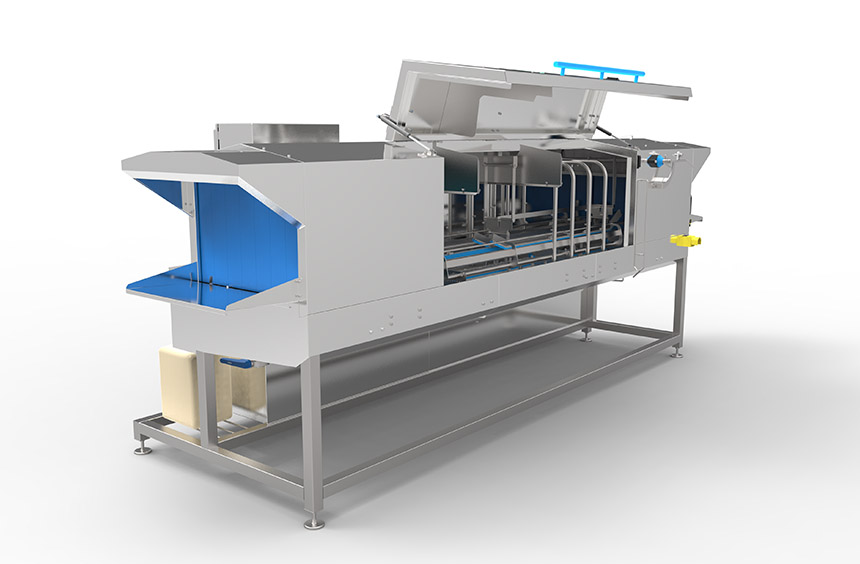

As it happens in others sectors, (f. e. in the bakery one), washing lines are included in the production line of the plant as an extra phase of the process. It means that moulds and trays, once they have passed by all the stages, they arrive empty at the washing and drying line where they are washed and dried, so when they leave the line they are automatically driven to the very beginning to start again the process.

This fact forces the washing machine manufacturers to respect very high hygienic standards and, over all, a perfect drying result, because, in very few seconds, moulds or trays are used again and filled with the product. So, the washing needs a minimum time of working to rid completely off the remains of sugar or chocolate, what needs to apply the appropriate mechanic effect without damaging the silicone that sometimes is easy to see in others moulds and trays.

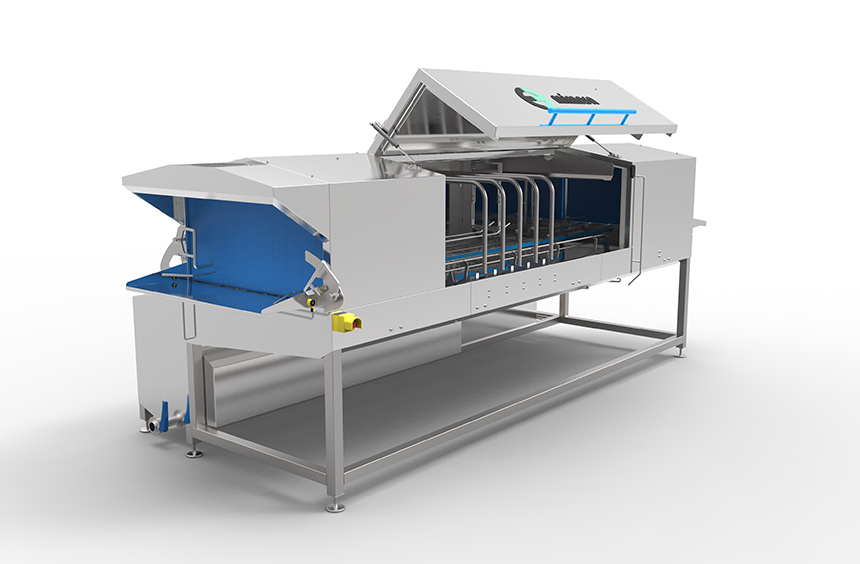

Last years, Mimasa has installed washing and drying lines for trays, bins, pallets, etc. The APPCC program, developed by Mimasa, able to display the estate of the important points of the hygiene in real-time and set an active control of these parameters to the point that the line can be stopped if something could risk the hygienic guarantee of the system; it is an ideal complement for these kind of installations. All Mimasa’s machines are tailored designed and made, according to the costumer’s needs.

Washers for the sector confectionery

Customized washers for the sector confectionery

![]()

Your tailor-made project

We design and manufacture tailor-made washing and sanitizing systems that are designed for each specific sector and companmy to fit their production needs.

+![]()

At your side

Mimasa is by your side during the entire process. We help you choose the right solution for your application, we provide start-up and training, and we provide after sale parts and service. We are here when you need us most.

+