- Sectors

- Poultry

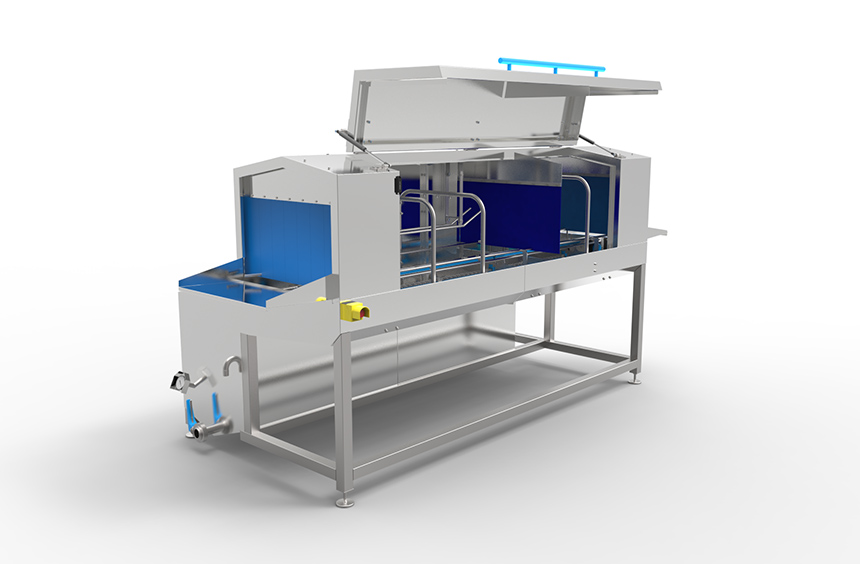

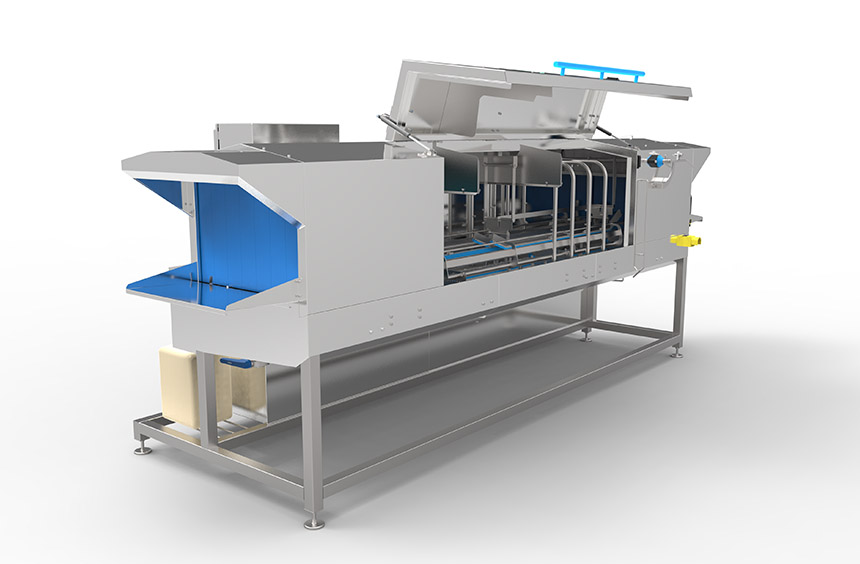

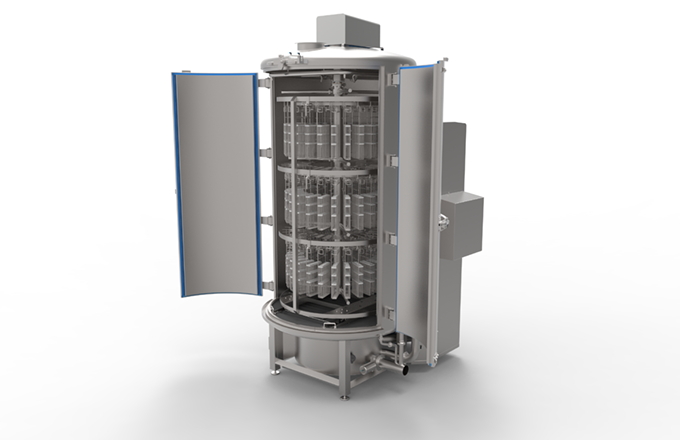

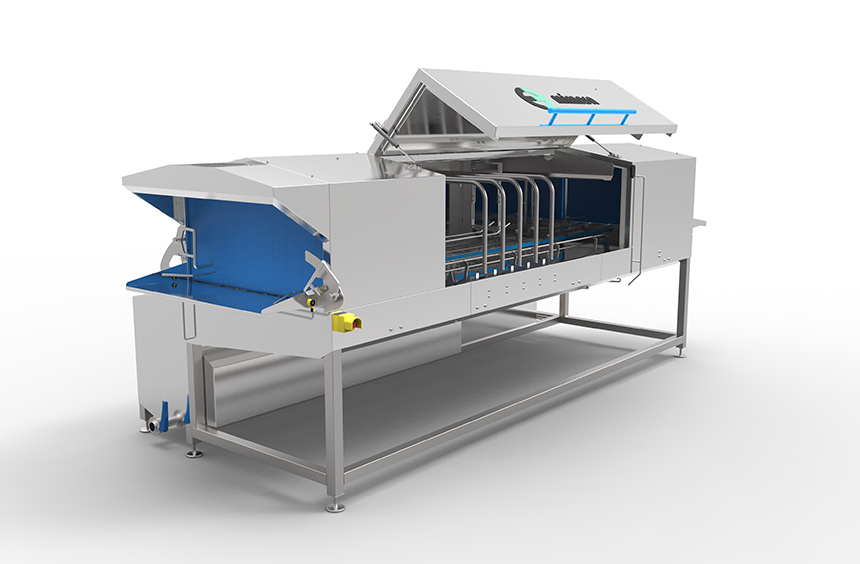

Washing systems

for the poultry sector

The poultry sector, in its aspect of slaughterhouses and cutting plants, and so in the processed products, is one of the most usual markets for Mimasa washing tunnels and cabinets. This sector is in most of the countries around the world, often with big production, usually concentrated in few production plants in each country.

Possibly due to this global presence of the production plants all over the world, but also for being large production plants in which food safety and hygiene measures are since many years ago, very important, many leading companies in this sector, at the international level, rely on Mimasa for their washing and disinfection projects.

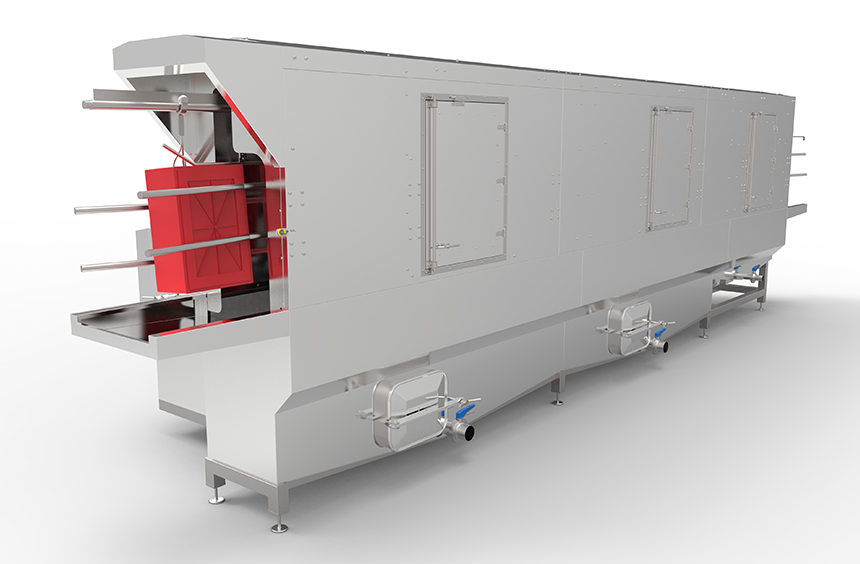

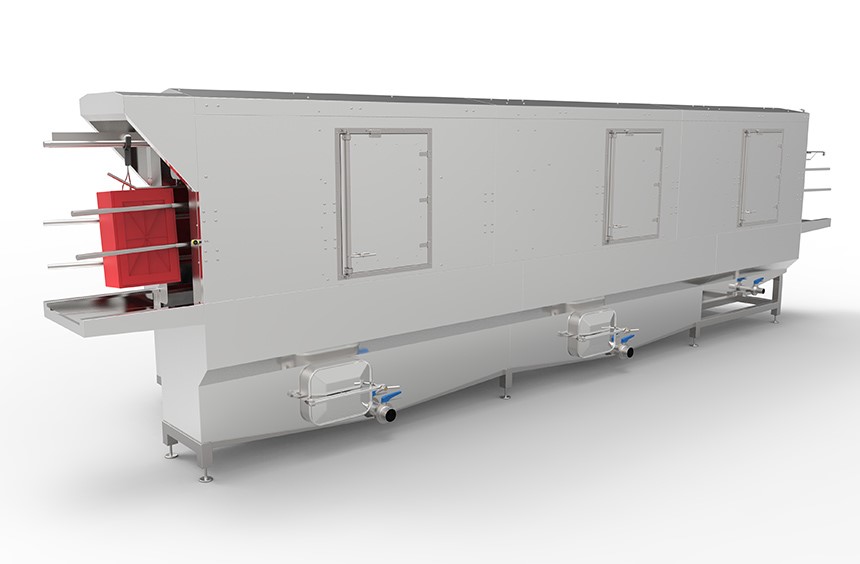

Although the most commonly installed lines in this sector are the overhead crate washers, in its multiple versions, there have been projects of cleaning of pallets, bins and plastic containers in general, as well as cabinets and washing tunnels for turkey racks or live animals transport crates. Still, possibly the most spectacular installations in this sector are large trucks washing tunnels of cages of 2.5 meters high.

Lately overhead crate washing tunnels are giving way to horizontal tunnels, mainly due to new trends in automation of internal circuits of crates, but also to make easy the removal of labels in the same washing tunnel or to improve the efficiency of the drying tunnels.

Washers for the sector poultry

Customized washers for the sector poultry

![]()

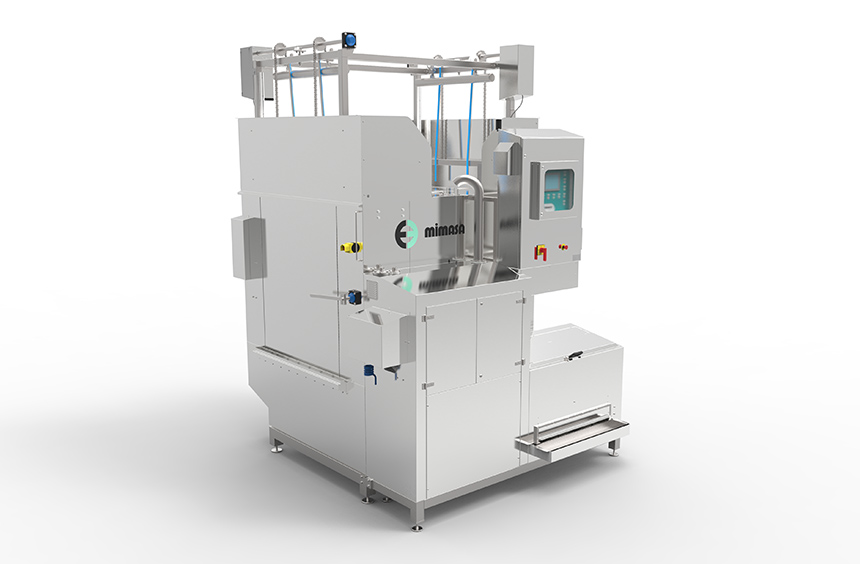

Hygienic Design

We apply hygienic design technology to all Mimasaa washing, sanitizing and drying systems. The three key concepts are: elimination of right angles, maximizing water flow, and giving maximum accessibility for cleaning.

+![]()

Your tailor-made project

We design and manufacture tailor-made washing and sanitizing systems that are designed for each specific sector and companmy to fit their production needs.

+