- Sectors

- Fish

Washing systems

for the fish sector

Fish sector, as many others from food industry, has experimented a technologic evolution tied to the traceability and control of the production processes that has updated its machinery along last years, as the fishing boats, harbors, fisherman associations, and so distribution and processing plants.

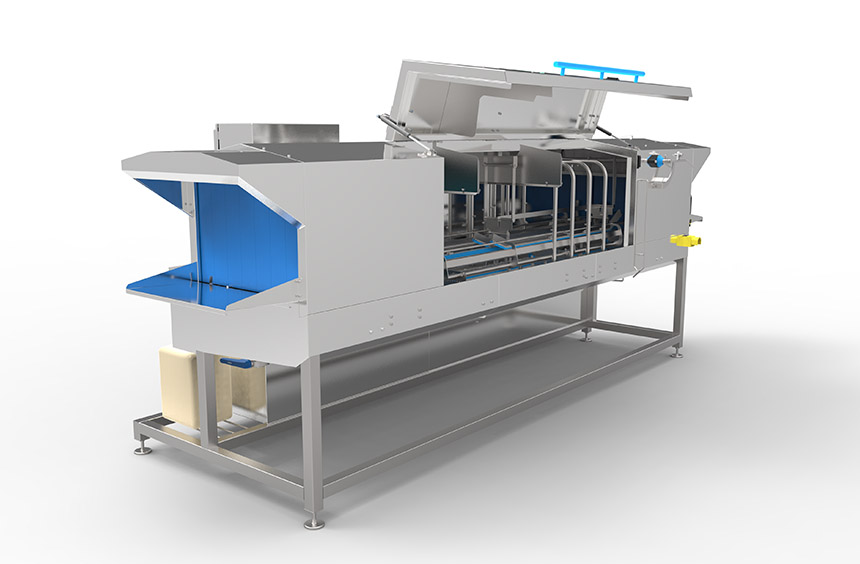

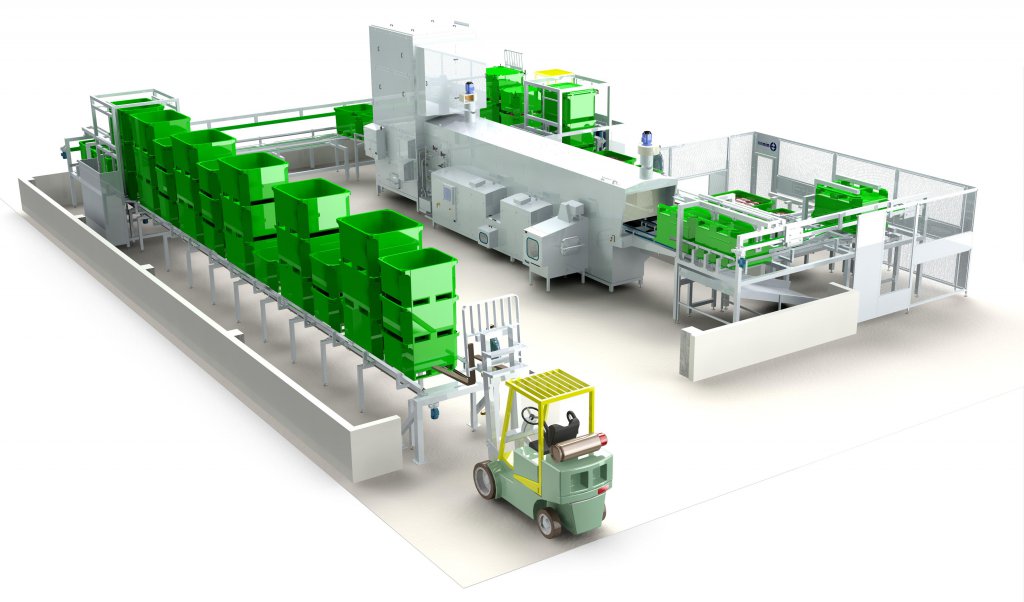

Fish sector is uses reusable transport elements like plastic crates, boxes, pallboxes, or so containers, plastic pallets, etc., in cases where the process involves a smokiness as the case of the salmon, or cooking as for example the tuna canneries, this is done using stainless steel trolleys which have especially residue, difficult to be removed and which are a real challenge for washing.

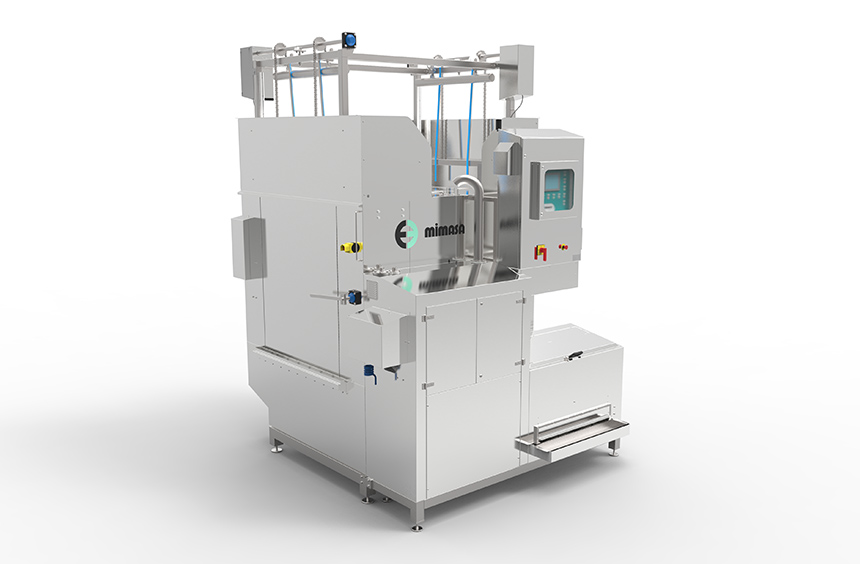

Mimasa, an international reference in the sanitization with the highest standards of quality and hygiene, can be considered as a partner of the sector, by this set of elements. Nowadays, Mimasa has machines for the fish industry around the world; from the demanding tuna trolley washing tunnels and cabinets, going through the usual bin washing lines in areas close to the harbor or next to it, and for ending the pallbox, bin and pallets washing tunnels and cabinets, in processors and distributors of fish.

In addition, due to the salinity of the waters, Mimasa offers the possibility to make with 316L stainless steel the areas in contact with the water in order to protect them from sea salt corrosion and lengthening, therefore, its life.

Customized washers for the sector fish

![]()

Your tailor-made project

We design and manufacture tailor-made washing and sanitizing systems that are designed for each specific sector and companmy to fit their production needs.

+![]()

At your side

Mimasa is by your side during the entire process. We help you choose the right solution for your application, we provide start-up and training, and we provide after sale parts and service. We are here when you need us most.

+