- Products

- Industrial sanitizing tunnels

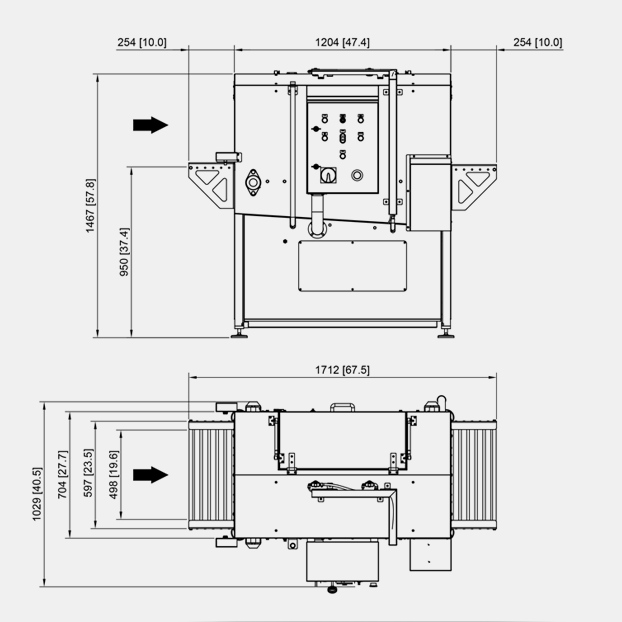

- Disinfection tunnel MD-100

The sanitizing tunnel MD-100 is the ideal solution for a perfect disinfection of the meat logs, cheese logs and other products, before getting into the cleanroom. Thanks to the atomizing technology we can disinfect all the geometry of the element, creating a thin protecting film. With a consume up to 8 times lower than traditional disinfection processes, the efficiency of these systems is unrivalled. Applications: disinfection of meat logs, products, trays, and any element before entering a cleanroom.

Mimasa Technology

-

Hygienic Design

Retention zones and 90º angles elimination, continuous welding, great accessibility. Let water flow!

-

Plug & Clean

We design our systems to be easy to assemble, install and connect.

Technical Features

-

Maximum clearance (WxH)

400x300mm

-

Production

14 meters/minute adjustable

-

Disinfectant dosing

By means of proportional pump

-

Chemicals application

Low consumption atomizing

- Options and accessories

- Sanitizer dosing systems

- Inlet and outlet conveyors

- Exhauster

Associated Machines

-

![]()

Hygienic Design

We apply hygienic design technology to all Mimasaa washing, sanitizing and drying systems. The three key concepts are: elimination of right angles, maximizing water flow, and giving maximum accessibility for cleaning.

+