- Products

- Crate washers

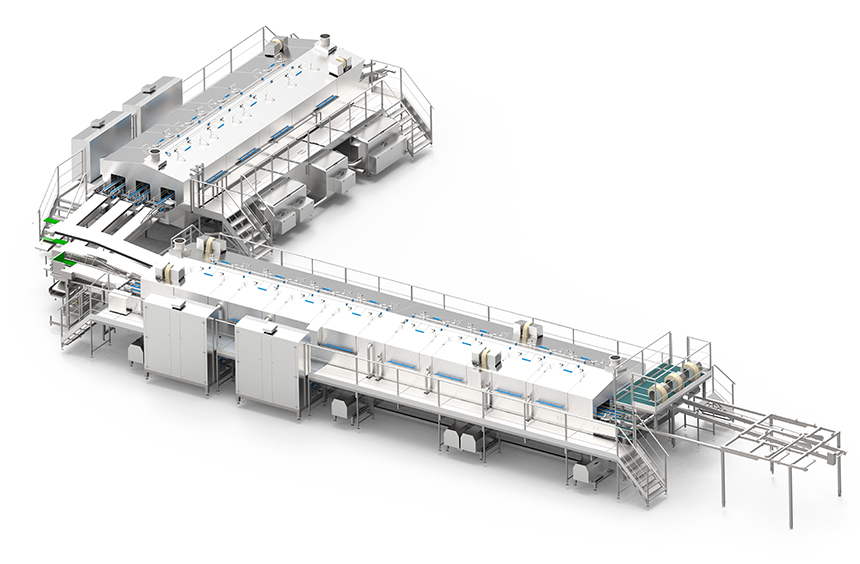

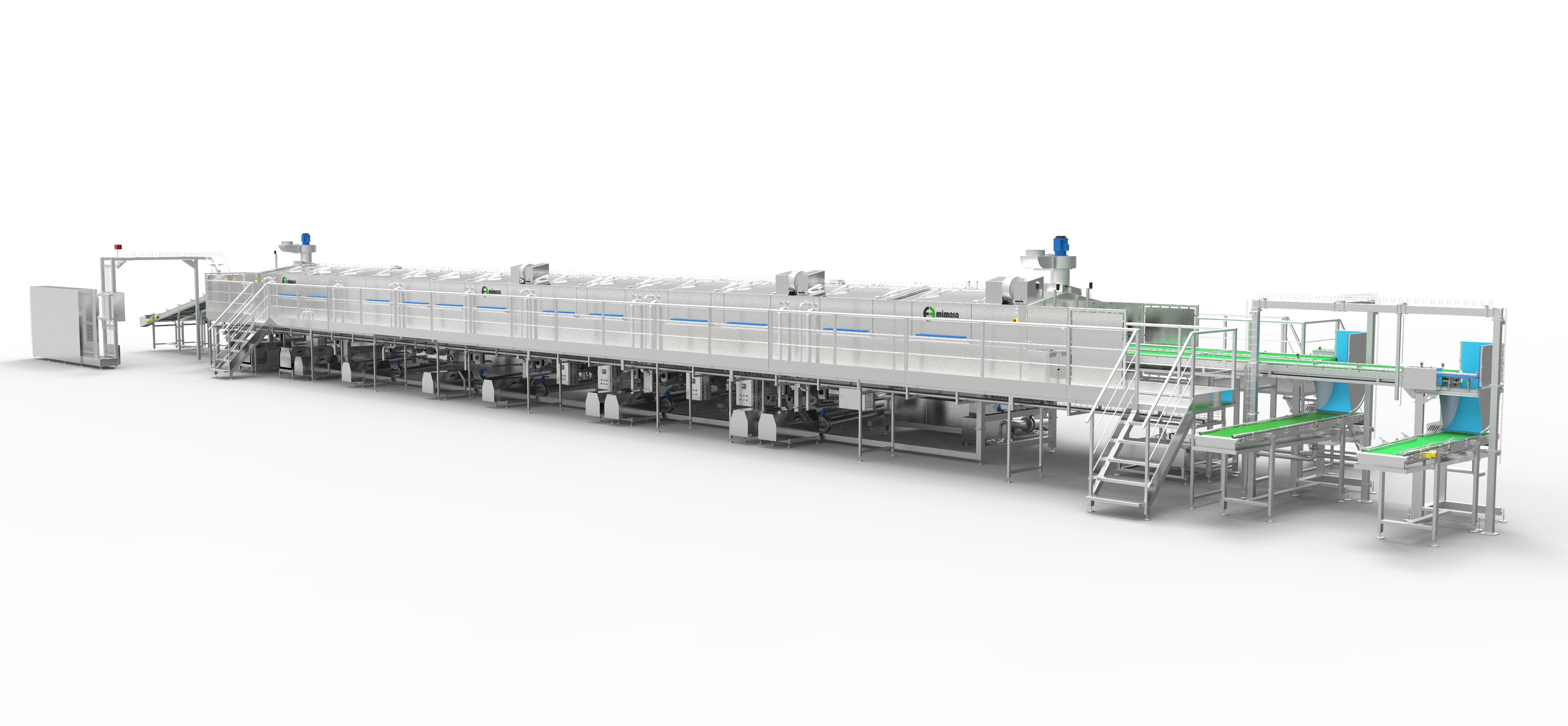

- Washers for high volumes of crates

More than 3.000 crates/h per lane with no stoppages

When talking about double and triple track lines, that must work continously 24h a day, details become much more important than ever. When we think in washing 6000, 8000, 9000 RPC's per hour in one single washer, nothing can be left to chance. Because every second counts and each one of the crates, RPC's, totes, boxes, must leave the system absolutely clean, no matter if the first or the last one of the shift. Is for that reason that Mimasa has developed, after many years and experiences at this level of exigency, a special line, totally focussed to obtain the highest productivities and a maximum cleaning quality, sustained all along the production hours.

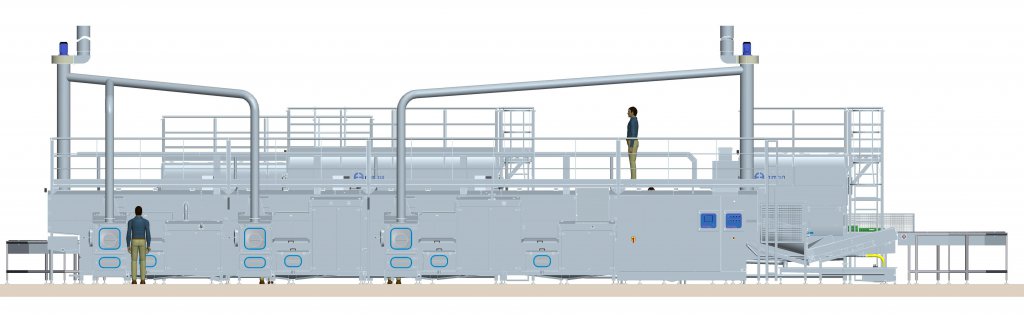

- Maximum efficiency in the accessibility

- Big sized doors with easy opening, much mor efficient than any other system in the market

- Access to the tanks area with no need to stop the washer

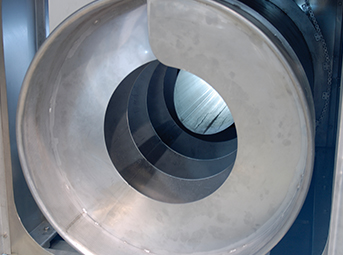

- Spin drying systems

- Advanced autodiagnostic and parameter control systems

-

![]()

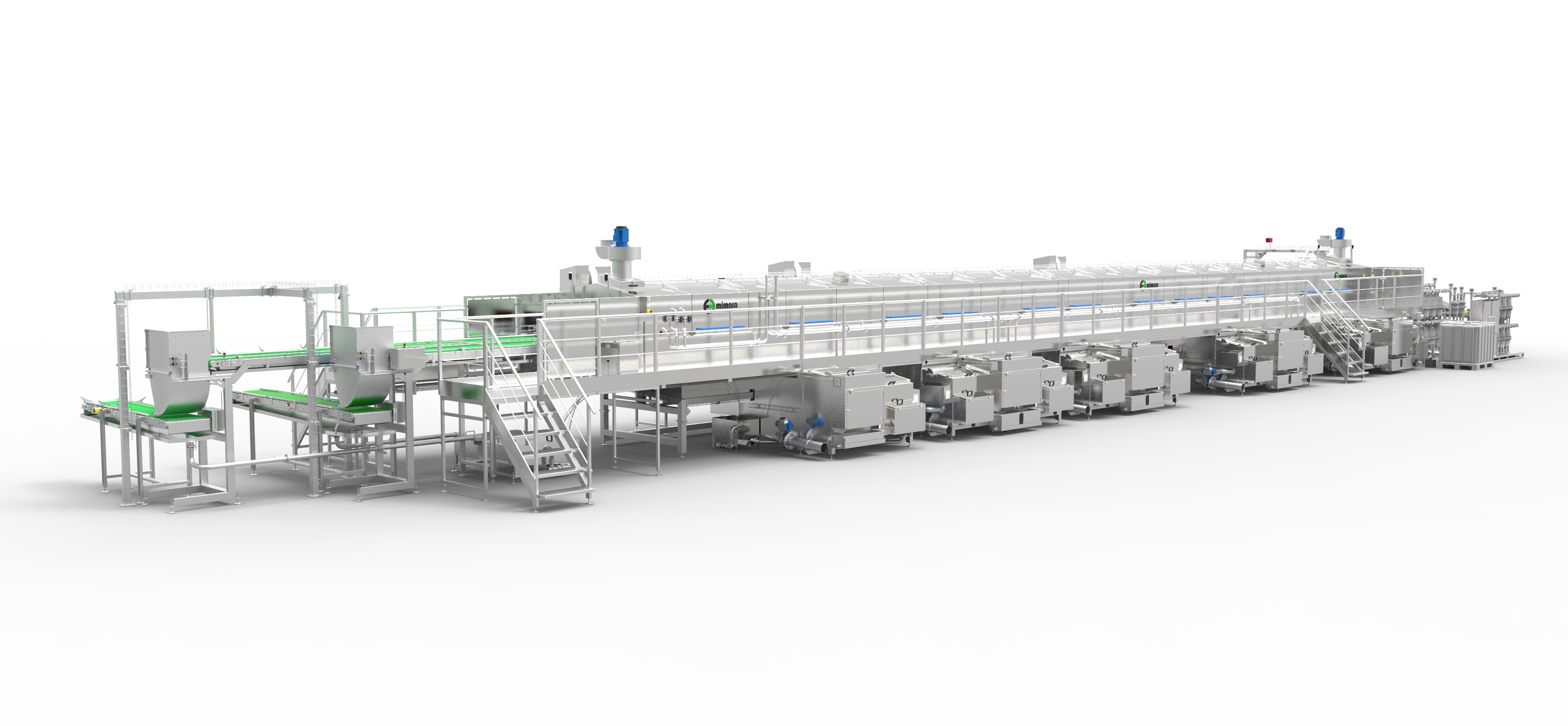

Plastic and papers labels removal from 4 sides. Speeds up to 9.000 crates/hour

-

![]()

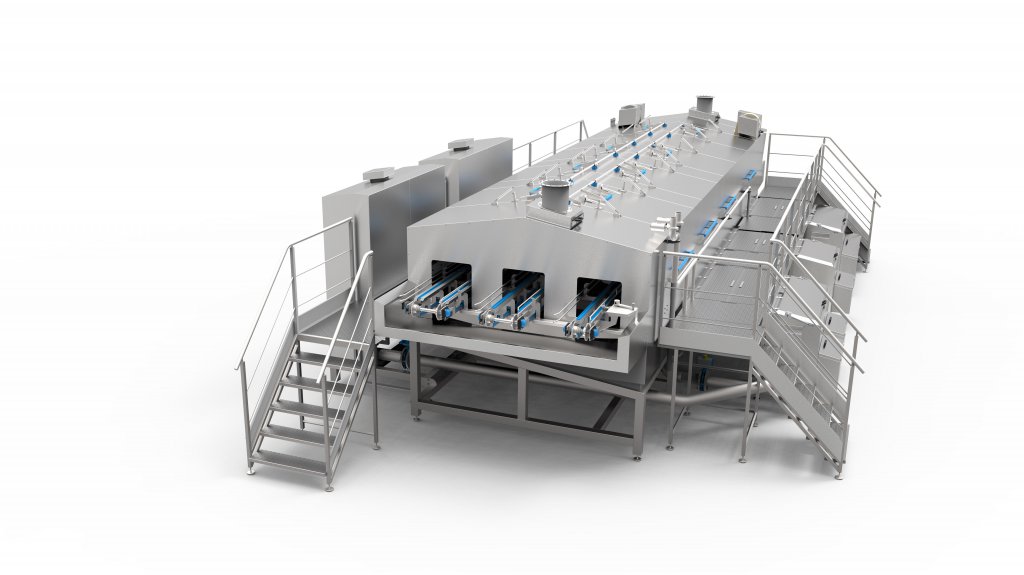

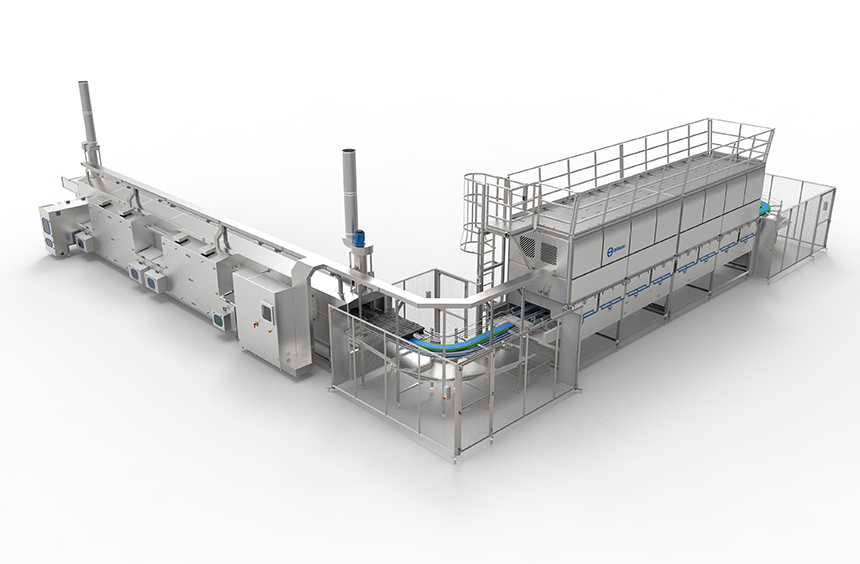

The best filters combination available in the market. Screw + rotary selfcleaning, an unbeatable combined solution

-

![]()

Unsorted washing. Crates of diferent sizes and heights mixed inside the tunnel

Mimasa Technology

-

Hygienic Design

Retention zones and 90º angles elimination, continuous welding, great accessibility. Let water flow!

-

Label Removal

Ready to be integrated in washing systems, for plastic and paper stickers, at any speed.

-

Born to be Automated

To facilitate the automatization of the sanitizing processes. Washing systems born to be automated.

-

Spin Dry

The spin-drying system that improves the drying results and reduces the consumption, the space and the operational costs.

-

The 10-Sides

TechnologyTen sides that need to be cleaned. Mimasa does not forget any of them.

Associated Machines

-

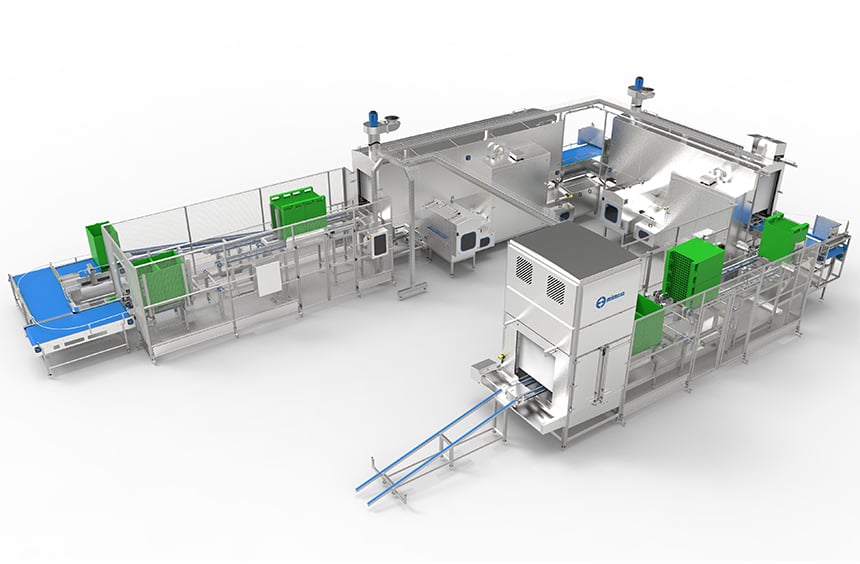

![]()

Your tailor-made project

We design and manufacture tailor-made washing and sanitizing systems that are designed for each specific sector and companmy to fit their production needs.

+