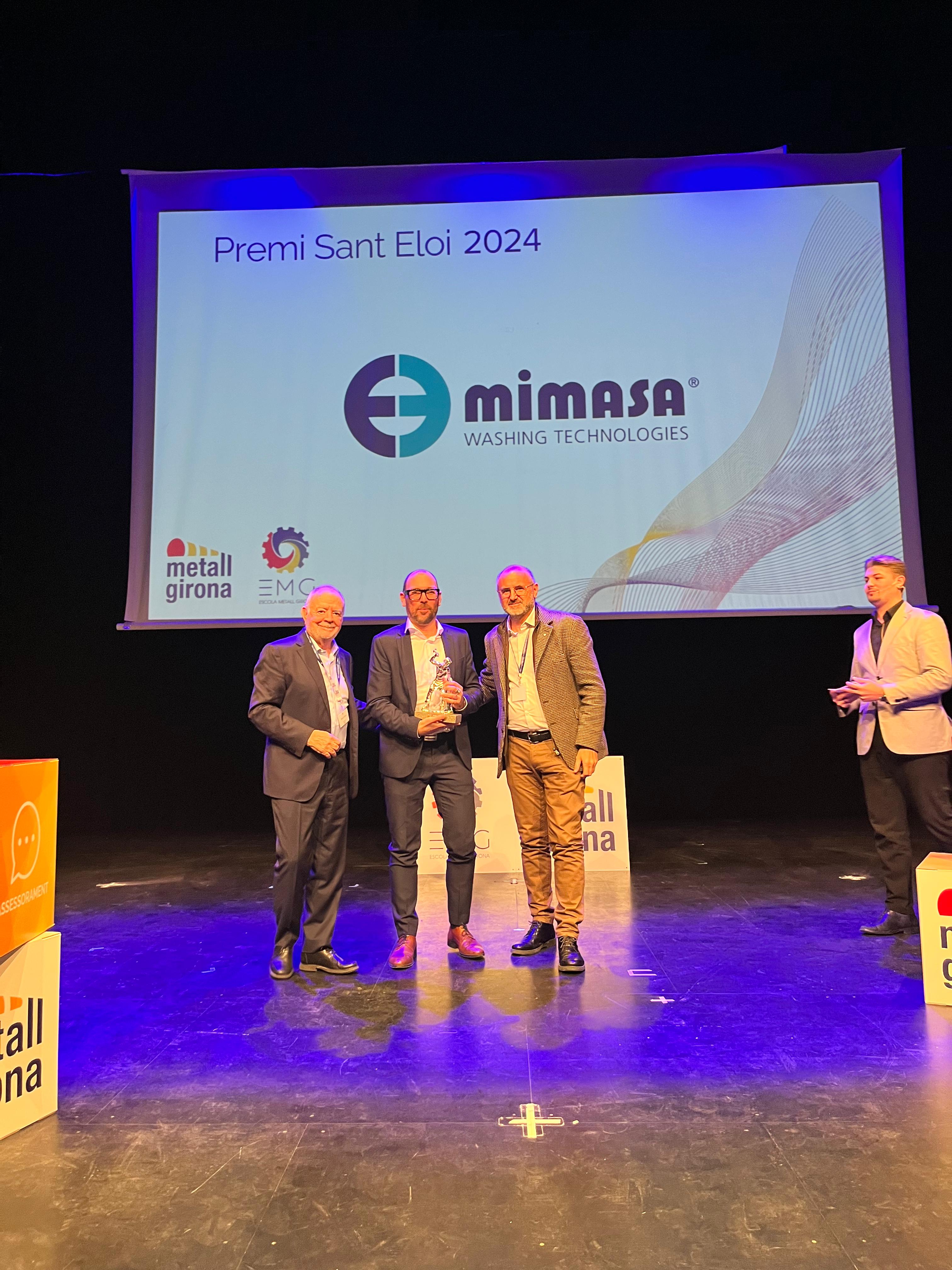

Mimasa Washing Technologies

-

![]()

![]()

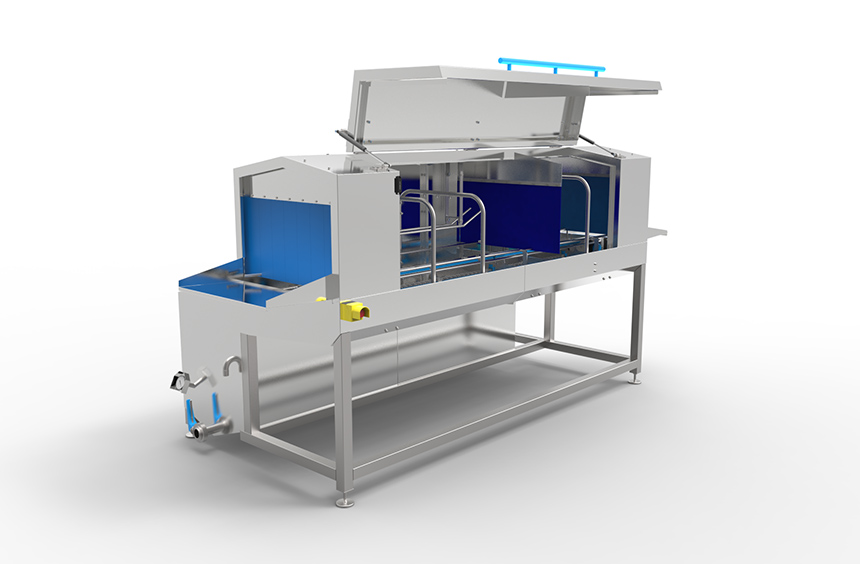

Hygienic Design

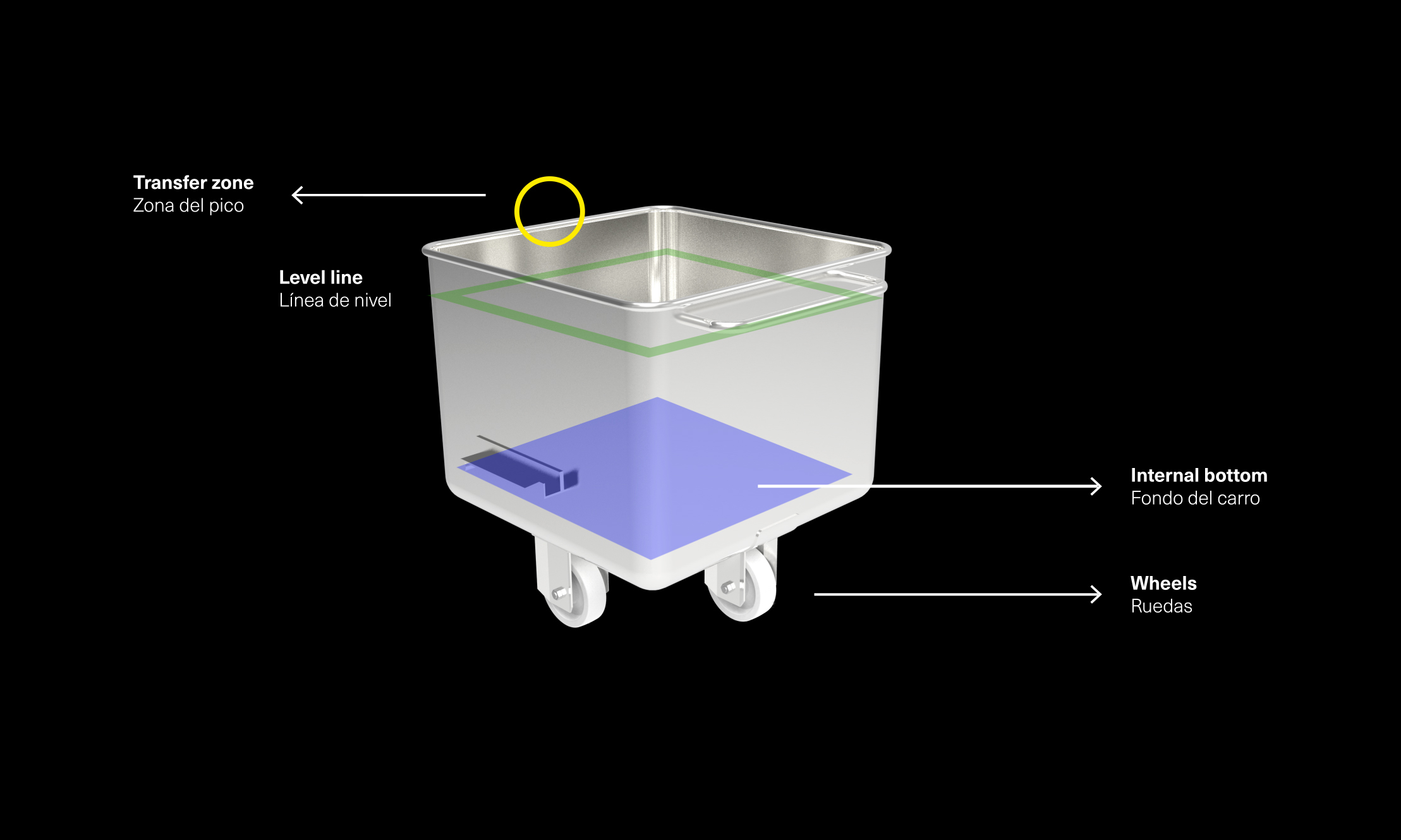

We apply hygienic design technology to all Mimasaa washing, sanitizing and drying systems. The three key concepts are: elimination of right angles, maximizing water flow, and giving maximum accessibility for cleaning.

+ -

![]()

![]()

At your side

Mimasa is by your side during the entire process. We help you choose the right solution for your application, we provide start-up and training, and we provide after sale parts and service. We are here when you need us most.

+ -

![]()

![]()

Mimasa DNA

We are aligned with global goals, protecting the planet and assuring the prosperity for all, as part of a new agenda for sustainable development.

+ -

![]()

![]()

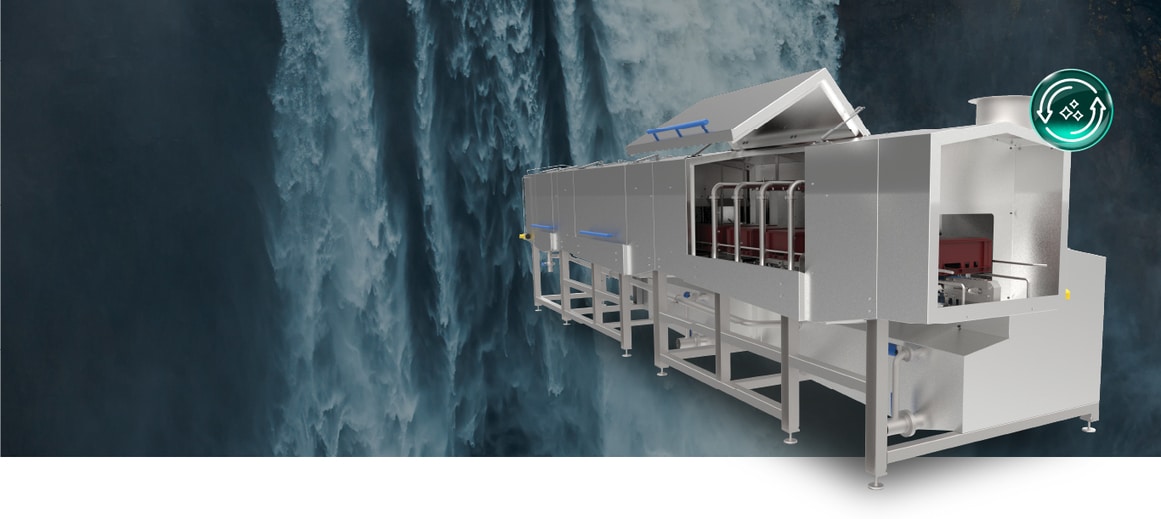

Your tailor-made project

We design and manufacture tailor-made washing and sanitizing systems that are designed for each specific sector and companmy to fit their production needs.

+

Which is your sector?

- Pool and Logistics

- Meat

- Fish

- Fruits & Vegetables

- Confectionery

- Bakery

- Cheese and Dairy

- Poultry

- Ready meals

- Food process

- Non-food

- Pharmaceutical

Washing systems

for the pool sector

The pool sector, dedicated to the rental and management of containers for the product transport (mainly from suppliers to large distribution chains) is a large share of our customers of washing systems. The reason is obvious: a pool rents clean containers. To have containers that are clean - you need to wash them... and wash them well. So, in a pool, crate washing tunnels, palets and pallbox are part of its main means of production.

Washing systems

for the meat industry

For geographic and historical reasons, Mimasa has been always very active in the meat sector. Both processes such fresh and processed use many kinds of containers and transport elements, which need to be cleaned and disinfected

Washing systems

for the fish industry

Fish sector, as many others from food industry, has experimented a technologic evolution tied to the traceability and control of the production processes that has updated its machinery along last years, as the fishing boats, harbors, fisherman associations, and so distribution and processing plants.

Washing systems

for the fruit & vegetable sector

Fruit and vegetable sector is characterized by reaching a wide range of products. The reason why it is in the biggest markets and so it is represented by lots of production structures and business. During the last years, export has been a determining factor for the growth of the sector.

Washing systems

for the confectionery sector

The confectionery sector has passed through into an important industrialization process in the last years. Specially, chocolate manufacturing lines, where the washing and drying of mould and trays is one of the most important points in the production lines due to the contamination risk.

Washing systems

for the bakery sector

The bakery sector has gone through a process of industrialization during the last years, especially bakery bread lines, which work non-stop with a high level of automation. The time used to rinse and to wash all the trays, bins and baking trays, now is shorter, what has become to a very critical point in the production lines.

Washing systems

for the cheese and dairy sector

One of the most outstanding aspects from cheese and dairy sector, a part from its presence all over the world, is the high automation level of their process and so the using of moulds and multi-moulds, within their lids, gives shape to the products.

Washing systems

for the poultry sector

The poultry sector, in its aspect of slaughterhouses and cutting plants, and so in the processed products, is one of the most usual markets for Mimasa washing tunnels and cabinets. This sector is in most of the countries around the world, often with big production, usually concentrated in few production plants in each country.

Washing systems

for the ready meals sector

Ready meal sector has grown non-stop all over the world these last years. This growth seems to be unlimited at short-term.

Washing systems

for the food process industry

The food process sector is so wide that is practically impossible to define all the subsectors. Sectors as the canning industry, wine industry, drinks and water industry or ice-cream industry for example, all them have production processes that use from plastic crates and pallets to boxes and special containers.

In these last years, Mimasa has installed crate, pallet, plastic container washing and drying lines and so others lines for special containers.

Washing systems

for any non-foodsector

Many other sectors have been in contact with Mimasa to develop tailor made solutions. Chemistry sector, petfood, automotive, reciclying and waste recuperators, subproduct, transport, logistics, components and a long list of other.

Washing systems

for the pharmaceutical sector

In the case of the pharmaceutical sector, the constructive and hygienic demanding of the sector as the 316L stainless steel, orbital welding, polished, roughness, EPA filters, etc, suppose washing and drying projects with a very accurate tailored design and management of the machine.