13 February 2024 / Articles

Articles

200L bins: four critical zones and one challenge

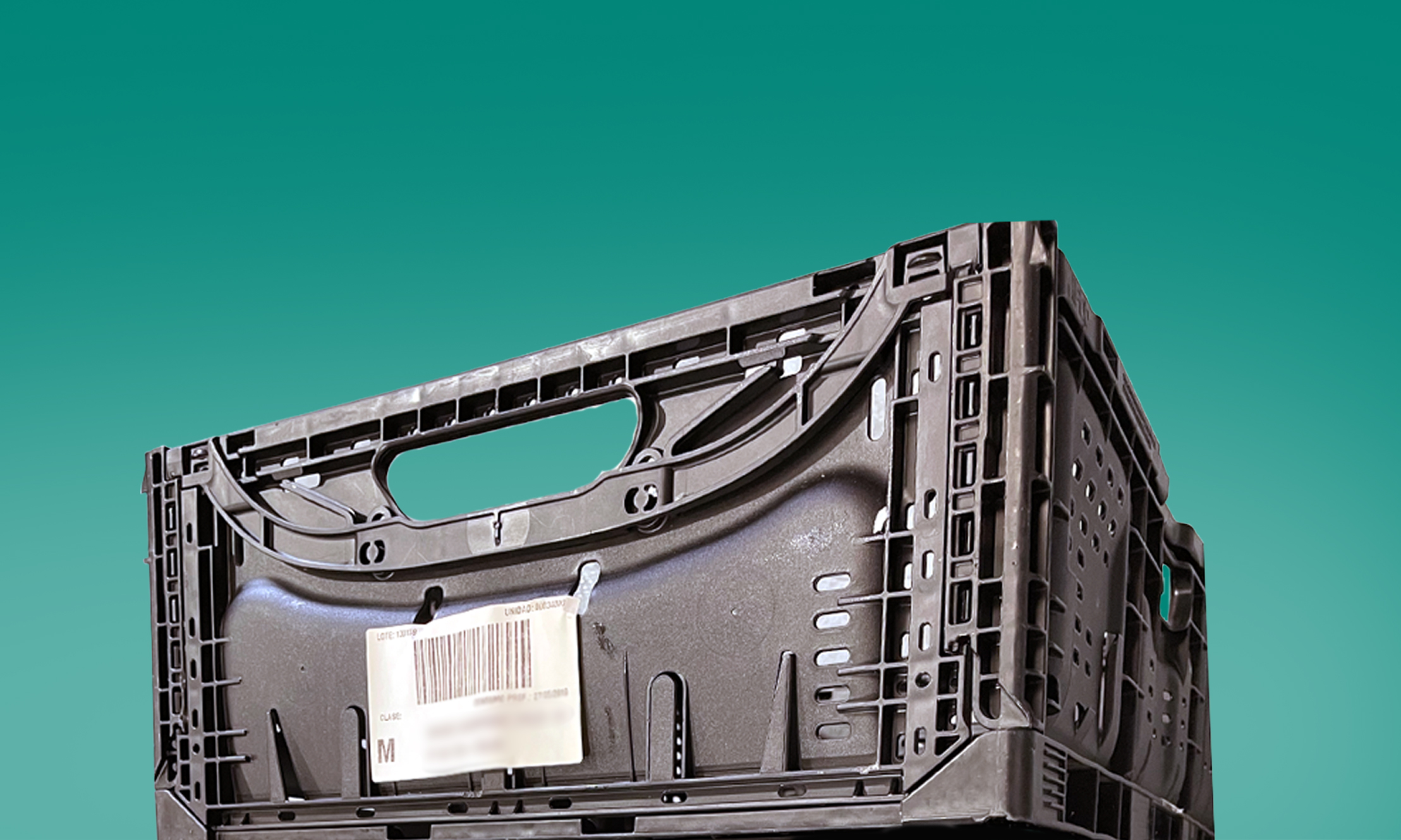

200L bin, Buggy, Bin, Trolley, Meat trolley, Vemag Cart, Eurobin... What name do you use when you refer to the 200 or 300 Liter containers with 4 wheels that feed the cutters?

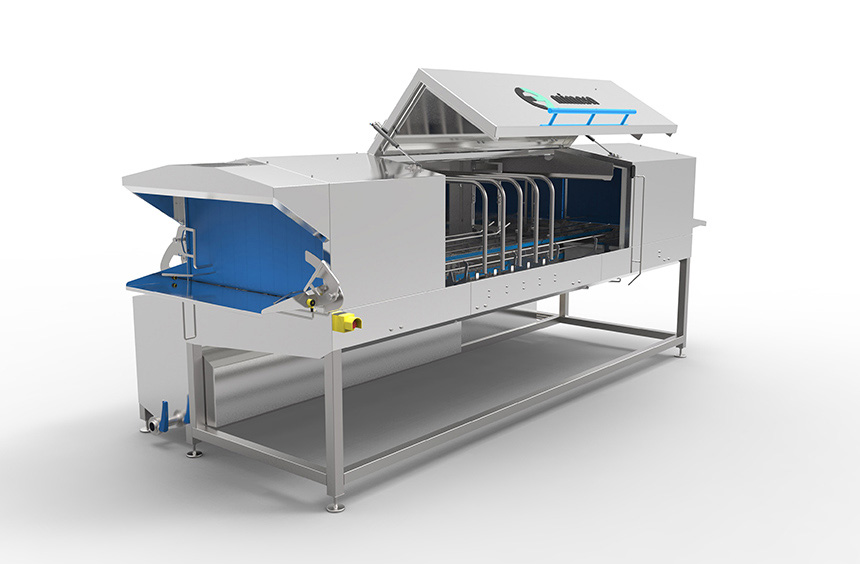

Beyond the name used, the kitchen cart with its characteristic 4 wheels located in the shape of a diamond and its side wings, is used by multiple companies in the food sector. Due to their peculiar shapes, the movements of these elements are not easy to automate. Washing and disinfecting has also several challenges. This article is the result of more than 30 years and a good number of experiences (not all of them positive...) in which at Mimasa we have faced the challenge of cleaning and disinfecting bins. We like to share our learning, exchange knowledge, learn and improve every day. That is why we invite you to collaborate with your comments, providing nuances, ideas that help us all learn.

4 Critical Zones.

Over the years, we have identified 4 critical areas to consider if we want to ensure the correct hygiene of the trolley:

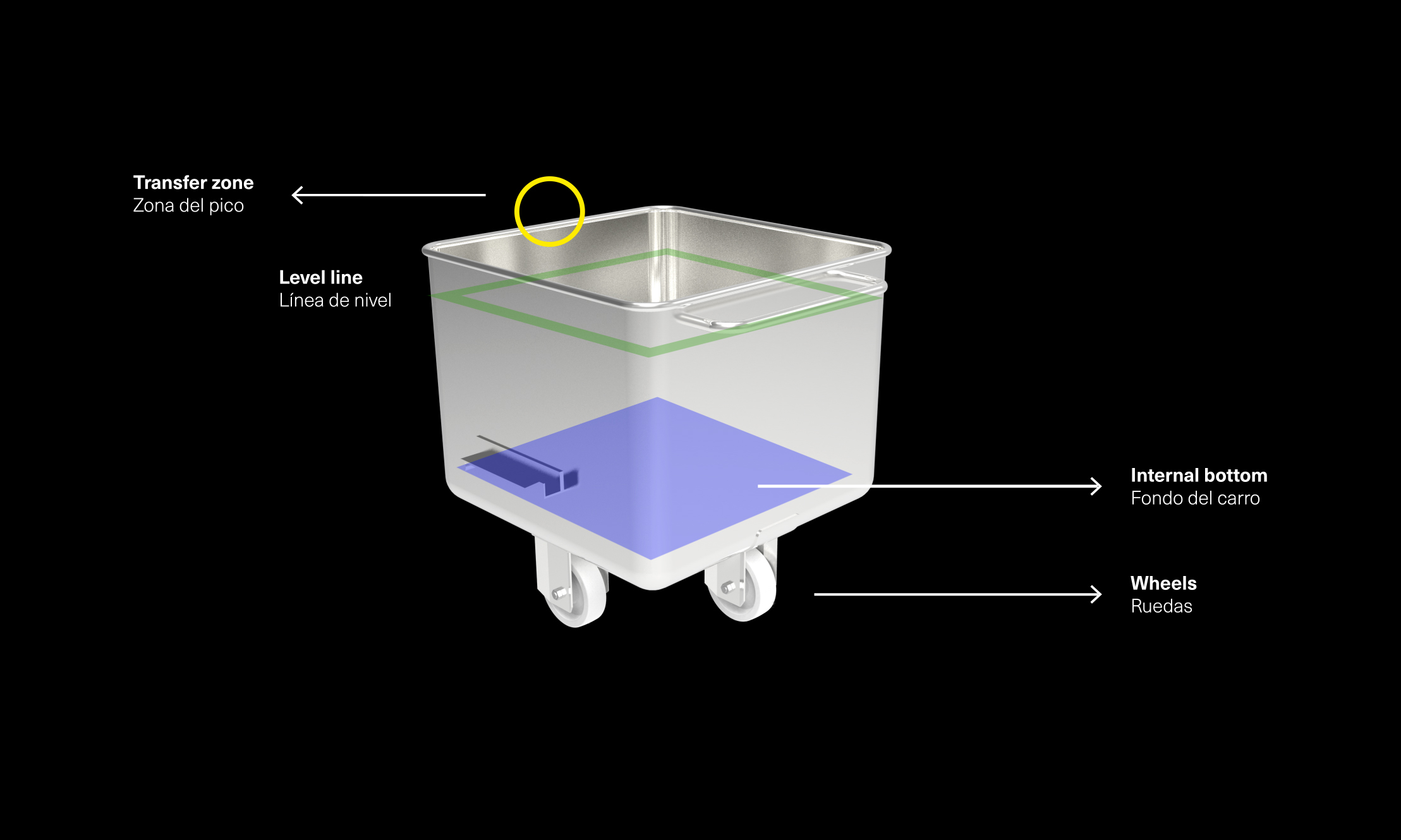

1. The peak area. It is the area through which all the product passes when it is transferred to another container. Normally the inner part is affected, but also the outer part. Therefore, it is essential that an automatic washing system has a very good impact on the external area of the trolley, and not only indirectly. We know from experience that hygiene cannot be guaranteed in areas that are not directly affected by a dedicated injector.

Tip: If you are going to install an automatic cleaning system, whether it is a cabinet or a tunnel: make sure that the washing of the exterior face is properly designed with a dedicated and correctly focused panel.

2. The contour line. In some applications, the product is stored in frigorific chambers for a few hours inside the cart. This causes the surface layer of the product to dry out a little and, in the areas that touch the walls, stick to the stainless steel. When the trolley is emptied, a line is then marked with product attached. We call this area the contour line. It is essential that the washing system dedicates an extra effort to this area, to ensure its correct cleaning. This point is more critical in the case of tunnels, where the conveyor can generate blind spots that the mechanical action does not directly impact.

Tip: if you are going to install an automatic cleaning system, especially if it is a tunnel: make sure that if the level line is generated in your production process, washing the inner face guarantees the impact on the entire level line.

3. Wheels: Hygiene problems in this area are more common in cabinet washers than in tunnels. It is common to find washing systems on the market that do not consider the importance of correctly impacting the wheel area. These are a source of cross-contamination, not only because of the transfer of dirt from one room to another, but also because, unlike other transport elements, the wheels of the cutter trolleys are not always on the floor and are not always below. Just imagine the moment when the typical automatic tipper empties the contents of the cutter into a tank.

Tip: If you are going to install an automatic cleaning system, whether it is a cabinet washer or a tunnel: make sure that washing the wheels has not been forgotten.

4. The bottom of the bin. In this case, the problem is not so much the washing itself but the danger of accumulated water once the cart has been cleaned. That the cart is well drained before turning it over again is an important point, especially if it is going to be unused for hours, since accumulated water is always a source of contamination. There are solutions to ensure the correct drainage, even forcing it.

Tip : If you're installing an automatic cleaning system, whether it's a cabinet or a tunnel: if water pooling at the bottom can be a problem for your process, make sure the system is properly designed to ensure a good drainage.

And a challenge:

Automation: Let's bust a myth: the sentence "all 200L bins are the same" is just not true. It is so false that not even within the same company are the same. Similar... Yes. identical... No. How does this affect us? When we install automatic systems for accumulation, turning, dumping...200L bins, we must be sure that the system will work without jams or problems. And to do this, all transport solutions must be designed to be robust against the geometric differences of the trolleys. It seems like a trivial topic, but it turns out that it is what gave us the most surprises in our first experiences with car automations. As with so many things in life, the only way to learn is to make mistakes and experiment. Moving bins, accumulating, turning them at high speeds, is a trade that can only be learned with experience.

Advice if you are considering a cleaning project with automations before or after washing: go with a company that has manufactured, suffered and learned from the automatic movements of bins. Do not forget that the 2D views and layouts can handle anything, but the mechanics end up imposing their law.

-

04 April 2023 / Articles

The Top 5 problems associated to the presence of labels on boxes, pallets and RPC’s

Over the years many customers from different sectors of the food processing have approached us to share their concerns about the presence of labels on their plastic boxes, as well as on pallets and other containers. In this article, we collect the most common concerns and share them with you, in case they can be useful.

Read more -

14 March 2023 / Articles

The energy impact: a top priority for the industry

Energy efficiency is at the center of concerns in the industrial world, and more and more companies are putting this priority at the center of their operations. Technological innovations are contributing to this transition towards a more sustainable model, where energy consumption is minimized and resources are used more responsibly.

Read more -

05 October 2022 / Articles

Sustainable performance and sustained results over time.

Investment in any type of washing and drying system is a project that is increasingly relevant within production. The industry faces needs and problems that must fit into the day to day of the company and respond, in addition, to concerns that go beyond productive capacities.

Read more -

12 April 2022 / Trade shows and events

Visit us at the upcoming trade fairs

This April and May, you will find us at ANUGA and IFFA, the reference events of the food industry.

Read more -

11 March 2022 / Ànima (soul)

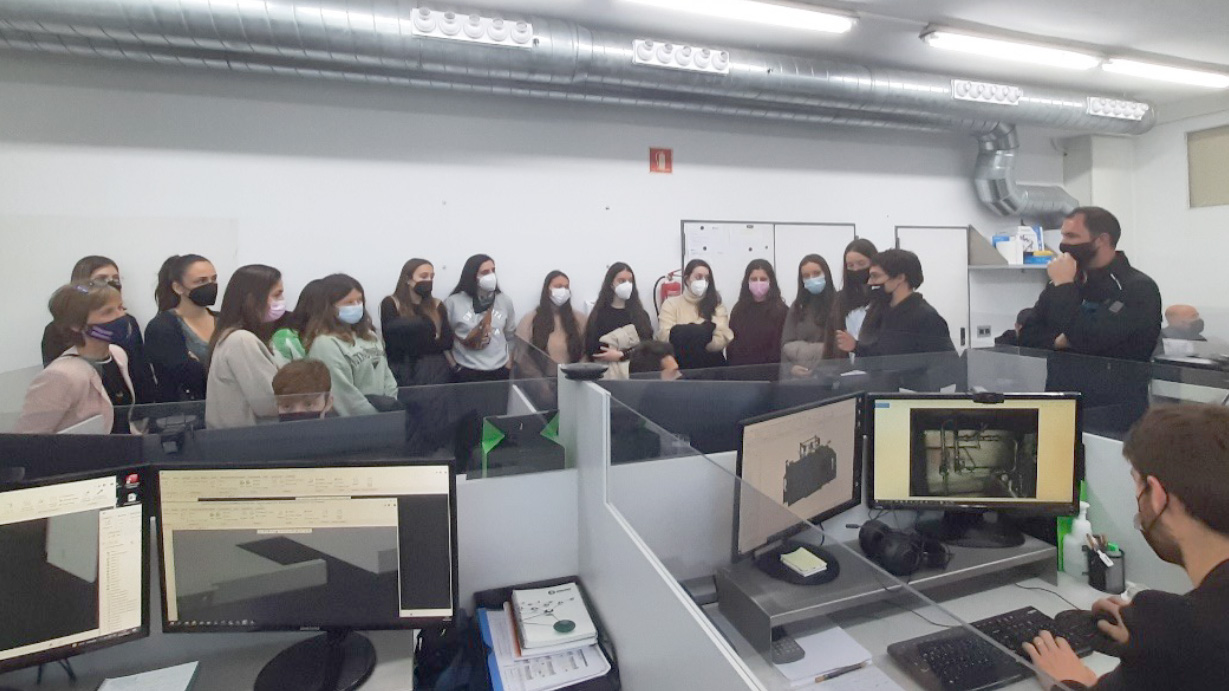

Working women international day

In celebration of the international day of working women, on March 8th we have been visited by 13 women students of engineering degrees and 2 professors of the Universty of Girona.

Read more -

25 November 2021 / Ànima (soul)

La Xarxa, an initiative of the Girona City Council, has awarded Mimasa for its commitment to promoting hourly reform, equality and work-life balance.

We are very excited to explain that Mimasa has been awarded with "Xarxa Gironina" prize for the Time Reform, in the EQUALITY and CONCILIATION category.Read more -

06 May 2021 / News

Mimasa Series | The standard washing and disinfection equipment that leads the way in the industry.

In these convulsive times, when we are all looking for references, our customers are clear that safety and hygiene are an indispensable solid pillar, which marks the path of the future.

Read more -

25 May 2020 / Ànima (soul)

Mimasa DNA

At Mimasa we have in our DNA the culture of effort and the will to improve and learn. We are curious. We believe in respect for people, close treatment and a good atmosphere at work. Without a doubt, being and wanting to be who we are has helped us a lot in this situation we live in. It has strengthened us.

Read more -

10 February 2020 / Trade shows and events

IPPE 2020 Atlanta United States

The fair was held from January 28 to 30, 2020 in Atlanta (USA).

Read more

04 April 2023 / Articles

The Top 5 problems associated to the presence of labels on boxes, pallets and RPC’s

Over the years many customers from different sectors of the food processing have approached us to share their concerns about the presence of labels on their plastic boxes, as well as on pallets and other containers. In this article, we collect the most common concerns and share them with you, in case they can be useful.

Read more14 March 2023 / Articles

The energy impact: a top priority for the industry

Energy efficiency is at the center of concerns in the industrial world, and more and more companies are putting this priority at the center of their operations. Technological innovations are contributing to this transition towards a more sustainable model, where energy consumption is minimized and resources are used more responsibly.

Read more05 October 2022 / Articles

Sustainable performance and sustained results over time.

Investment in any type of washing and drying system is a project that is increasingly relevant within production. The industry faces needs and problems that must fit into the day to day of the company and respond, in addition, to concerns that go beyond productive capacities.

Read more12 April 2022 / Trade shows and events

Visit us at the upcoming trade fairs

This April and May, you will find us at ANUGA and IFFA, the reference events of the food industry.

Read more11 March 2022 / Ànima (soul)

Working women international day

In celebration of the international day of working women, on March 8th we have been visited by 13 women students of engineering degrees and 2 professors of the Universty of Girona.

Read more25 November 2021 / Ànima (soul)

La Xarxa, an initiative of the Girona City Council, has awarded Mimasa for its commitment to promoting hourly reform, equality and work-life balance.

06 May 2021 / News

Mimasa Series | The standard washing and disinfection equipment that leads the way in the industry.

In these convulsive times, when we are all looking for references, our customers are clear that safety and hygiene are an indispensable solid pillar, which marks the path of the future.

Read more25 May 2020 / Ànima (soul)

Mimasa DNA

At Mimasa we have in our DNA the culture of effort and the will to improve and learn. We are curious. We believe in respect for people, close treatment and a good atmosphere at work. Without a doubt, being and wanting to be who we are has helped us a lot in this situation we live in. It has strengthened us.

Read more10 February 2020 / Trade shows and events

IPPE 2020 Atlanta United States

The fair was held from January 28 to 30, 2020 in Atlanta (USA).

Read more